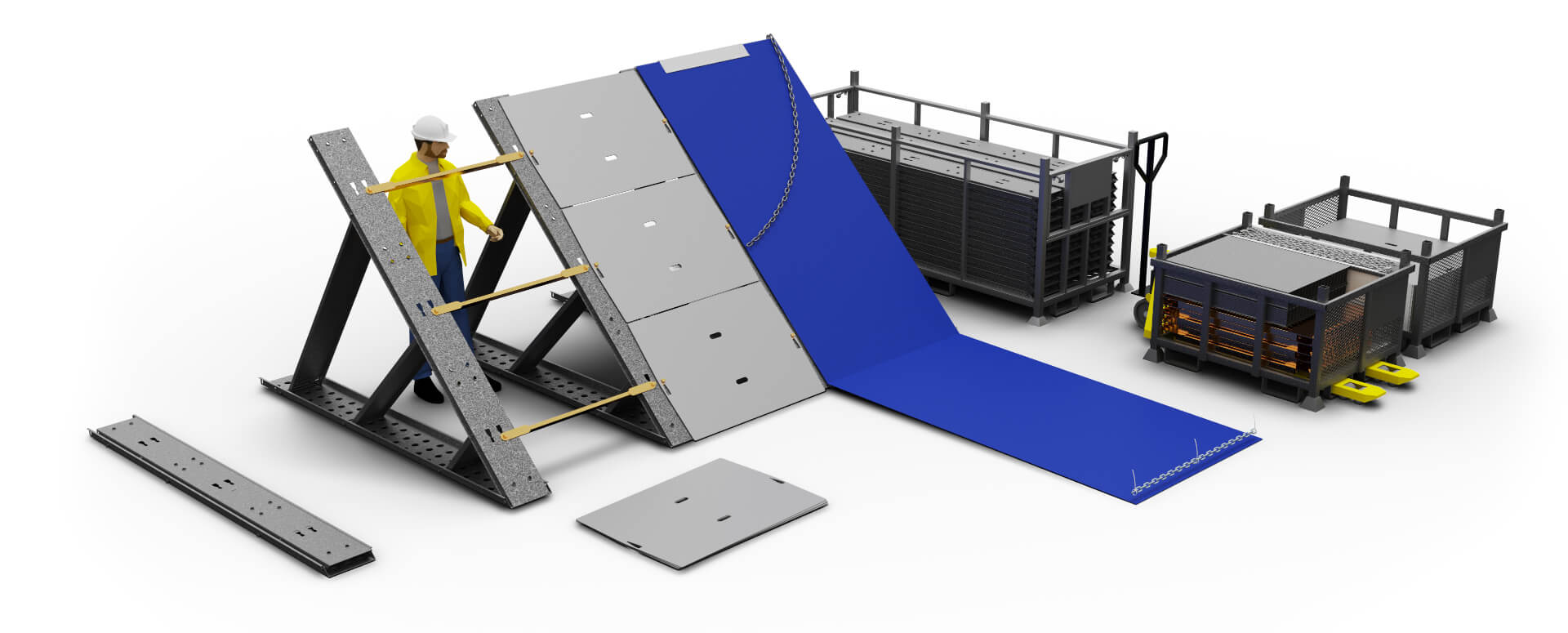

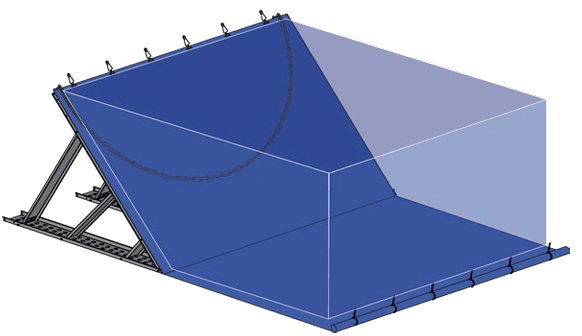

The C184 is one of the largest models in our Heavy Duty line, engineered for exceptional strength and durability. Each module uses three aluminum panels to achieve an impressive 184 cm protection height. Despite its substantial size, the C184 allows for efficient installation and maintains the exceptional structural integrity and stability that define the entire Heavy Duty series.

Dam height

184 cm

Module width

C/C

122 cm

Deployment time

(100 m / 6 people)

1 h 25 min

Storage volume

(100 m)

17,1 m3

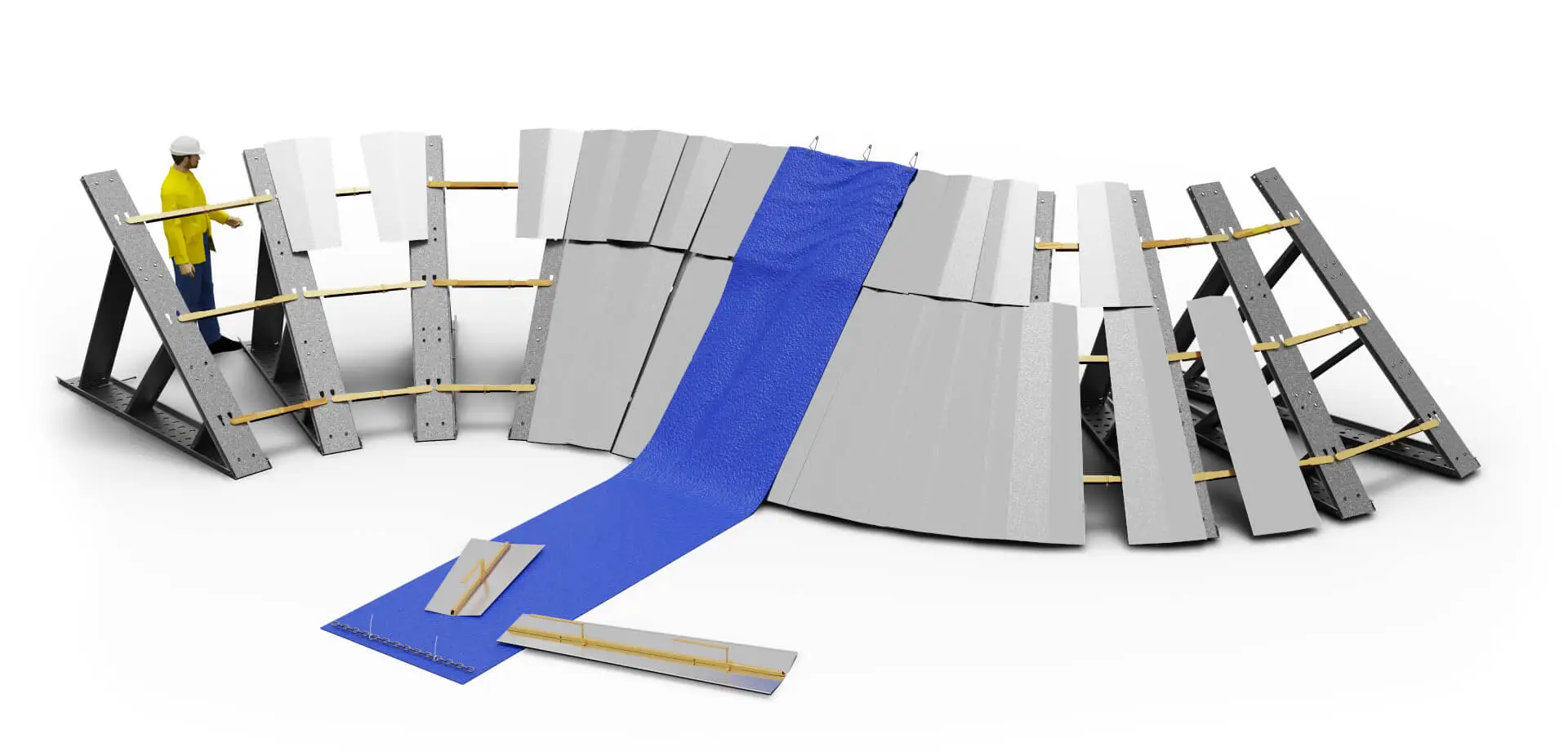

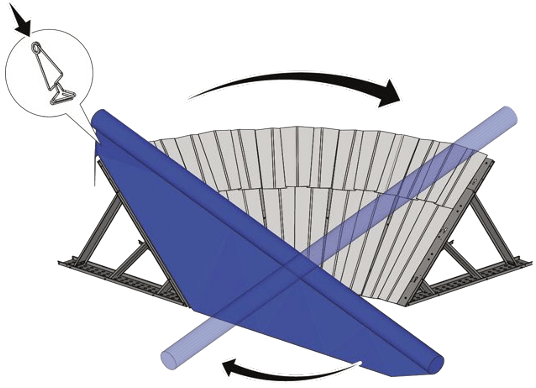

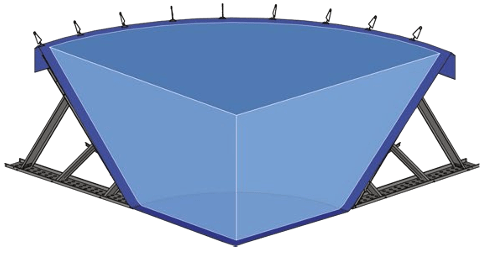

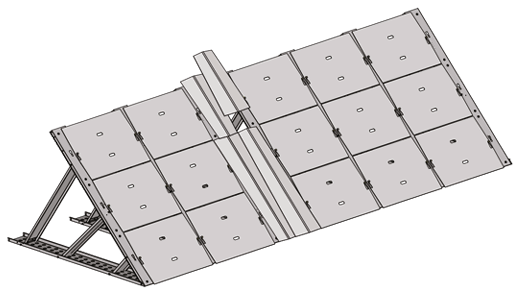

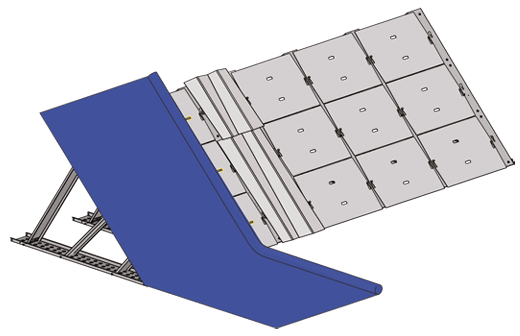

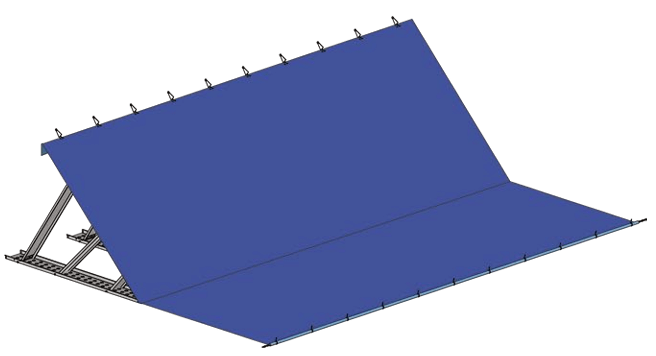

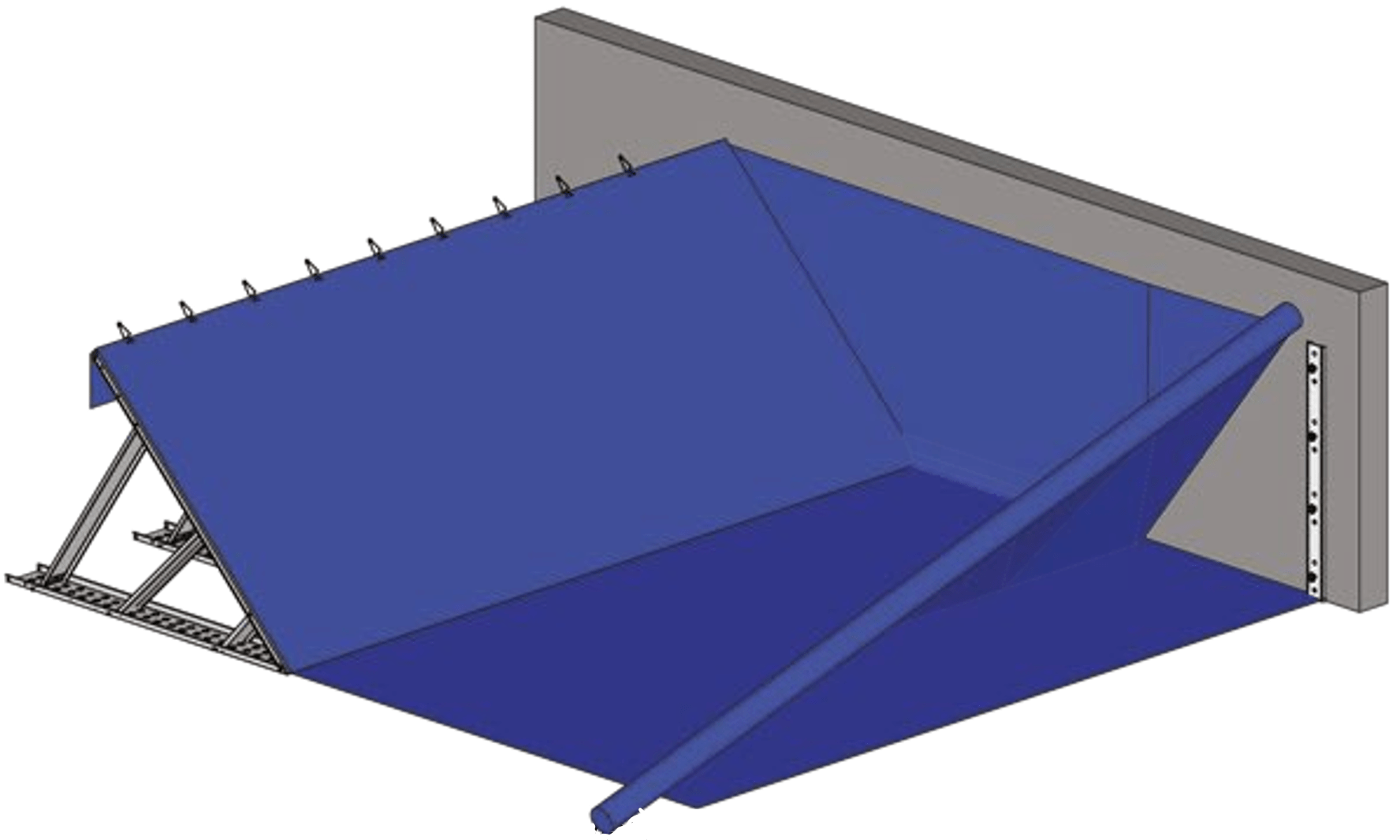

Introducing the C184 Heavy Duty flood barrier — a high-performance member of our Heavy Duty series. Like its siblings, the C184 employs a triangular metal support frame that unfolds and is held in place by three horizontal connection rods. Aluminum panels are hung onto these rods, and the entire barrier is sealed against the ground by a laminate-coated, high-density polyethylene membrane.

As with all Geodesign Barriers, the C184 can be deployed without tools, machinery, or ground preparation. Rising water pressure acts to push the barrier into the substrate, creating a self-anchoring effect.

Whereas the C152 uses two aluminum panels and two rods to bring the barrier to 152 cm, the C184 extends this design to reach a dam height of 184 cm. This makes the C184 ideal when you need a robust flood barrier that still benefits from the streamlined setup and reliability of our Heavy Duty system — balancing greater height with efficient deployment.

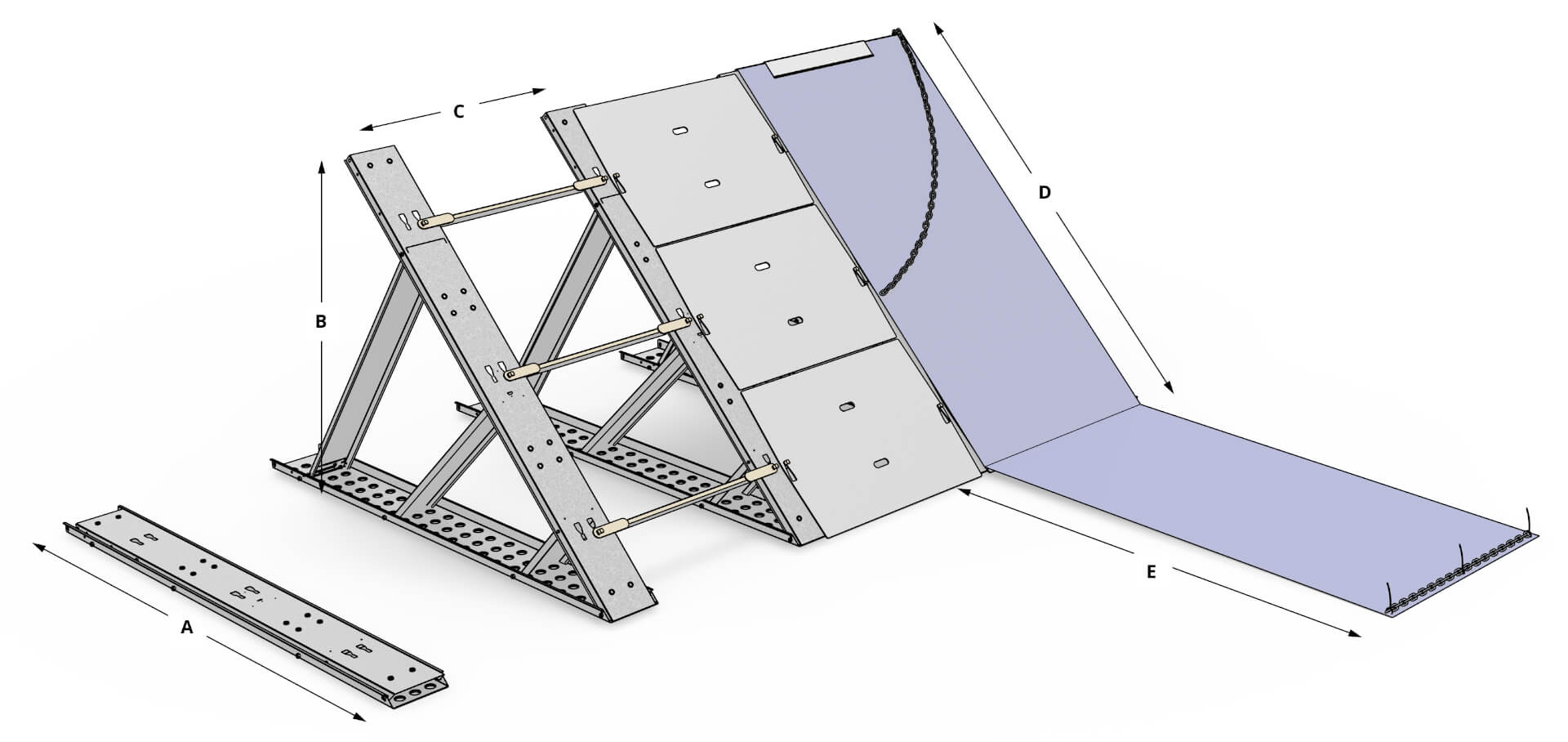

| Barrier footprint without membrane (A) | 269 cm |

| Maximum water column / Dam height (B) | 184 cm |

| Module width (C) | 122 cm |

| Inclined length (D) |

260 cm |

| Membrane ground length (E) | 398 cm |

| Membrane width (E+D+20 cm) | 700 cm |

| Installation footprint (A+E) | 665 cm |

| Set up time 100 metres by 6 workers | 1 h 25 min |

| Certifications | FM Approval ANSI 2510-2020 |

| Module weight | 106,8 kg |

| Water flow resistance | Performance verified at 2,13 m/s |

| Extendable | +15 cm or +61 cm to C245 |

| Factor of safety | 1.5 |

| Load / module | xxx kN |

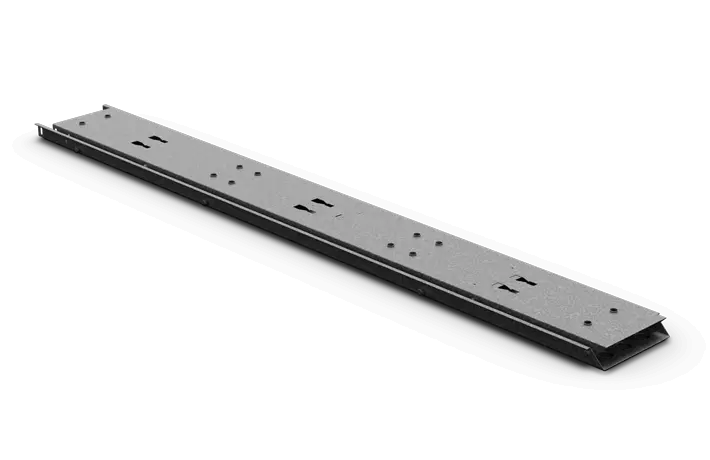

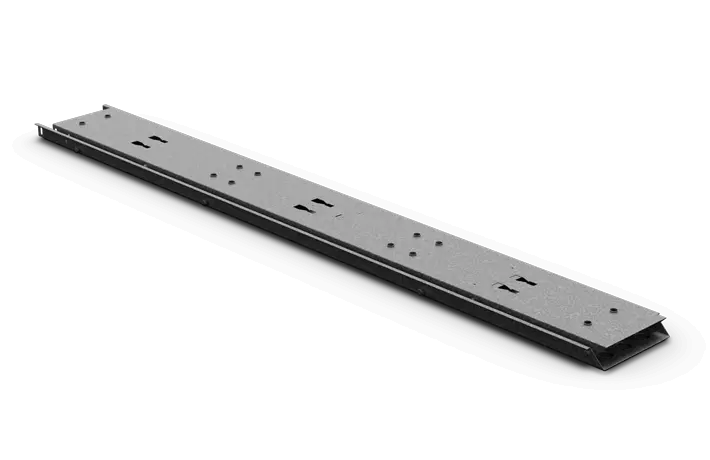

| Material | High strength low alloy steel |

| Dimensions | L 223 x W 32 x D 7,6 cm |

| Weight | 40 kg |

| Quantity / module | 1 pc |

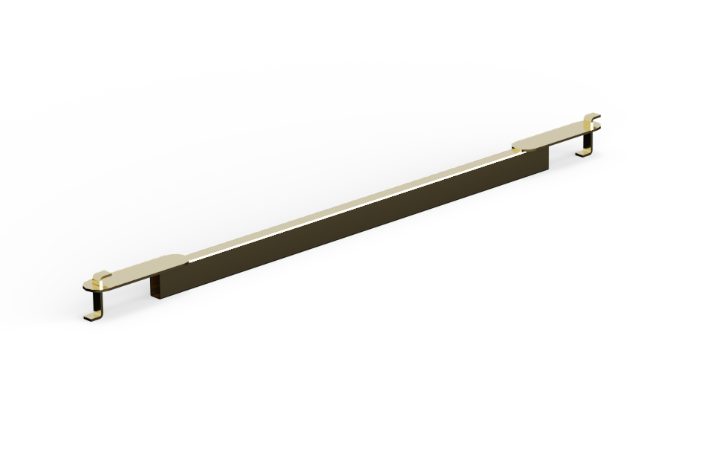

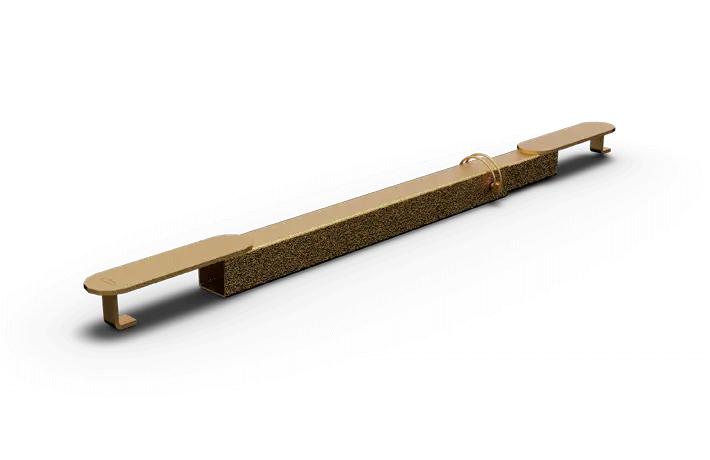

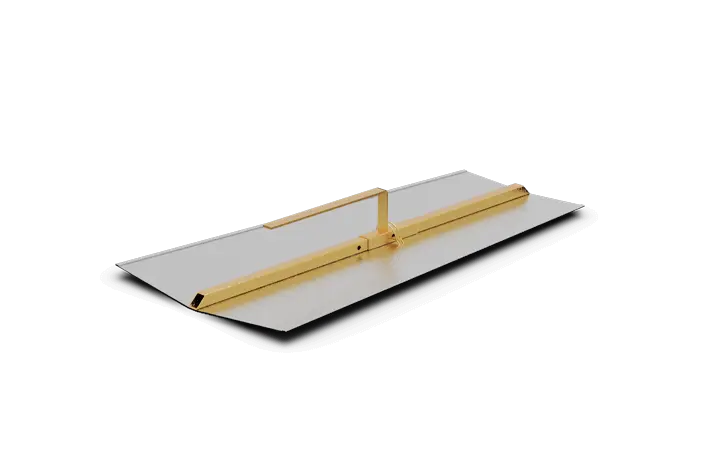

| Material | High-strength steel |

| Dimensions | L 122 x W 5 x D 7 cm |

| Weight | 3 kg |

| Quantity / module | 3 pcs |

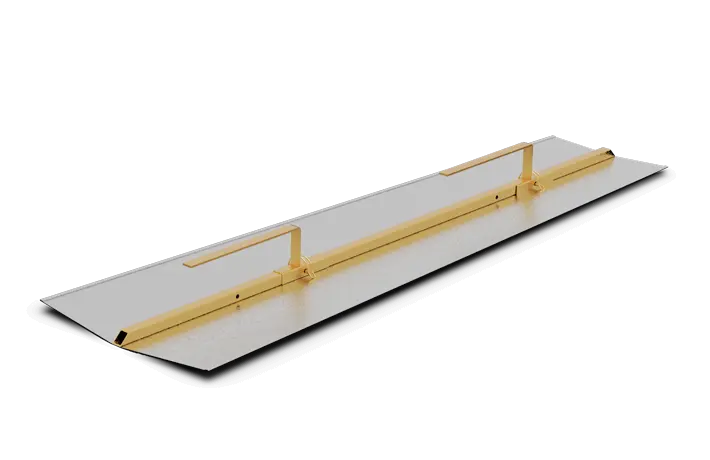

| Material | Aluminium checker plate |

| Dimensions | L 120 x W 86 x T 0,7 cm |

| Weight | 14 kg |

| Quantity / module | 3 pcs |

| Material | PVC coated low density polyethylene |

| Dimensions | L 50 x W 7 m - 140 g/m2 |

| Weight | 48,5 kg per roll |

| Quantity / module | 1,2 m / 0,024 roll |

| Material | Galvanized steel DIN766 |

| Dimensions | L 5 m x 12 mm links excluding carabiners |

| Weight | 15,6 kg |

| Quantity / module | 3,7 m / 0,8 pcs |

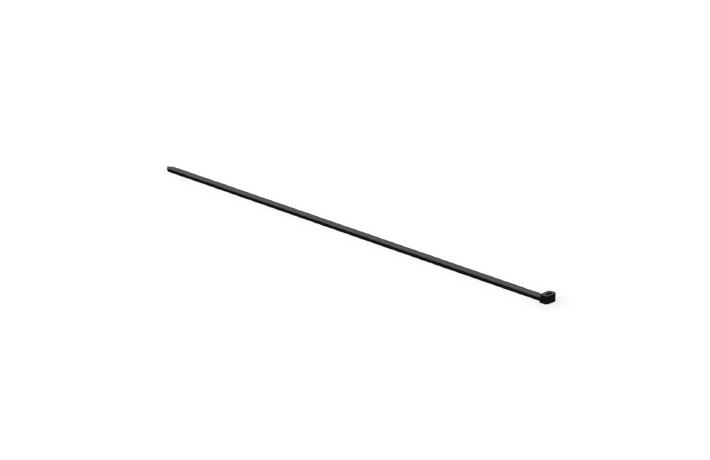

| Material | Nylon |

| Dimensions | L 38 cm |

| Weight | 0,001 kg |

| Quantity / module | 2 pcs |

| Material | High strength low alloy steel |

| Dimensions | L 80 x W 12,5 cm |

| Weight | 3,7 kg |

| Quantity / module | 1 pc |

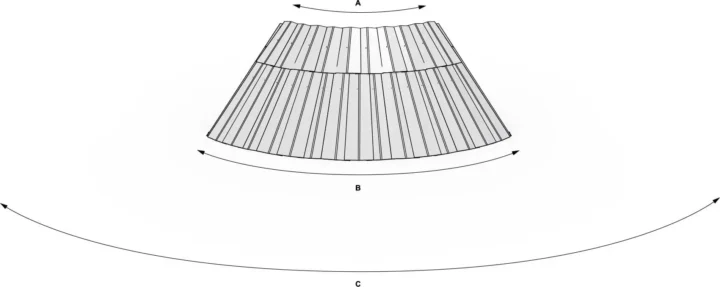

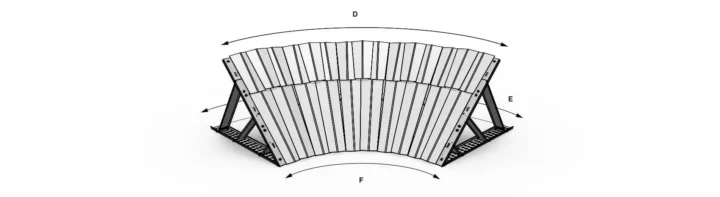

The C184 Heavy Duty flood barrier is built for precision and adaptability, with each corner module capable of turning up to 18 degrees. A 90-degree corner is formed by connecting five corner modules, enabling accurate alignment around complex site geometries.

Adjustable link bars and precision-engineered corner elements ensure quick, secure assembly and seamless transitions. Designed for both inner and outer turns, the C184 maintains excellent stability and a clean barrier line — even in demanding configurations and uneven terrain.

| Corner module splay angle | 18 degree |

| 90 degree corner | 5 corner modules |

| Setup time 90° corner (6 workers) | 15 min |

| Outer corner module weight | 121 kg |

| Inner corner module weight | 115 kg |

| Top edge arc length (A) | 325 cm |

| Base edge arc length (B) | 620 cm |

| Membrane developed length (C) | 1240 cm |

| Turning radius | 395 cm |

| Corner module splay angle (G) ¹ | 18° |

| Corner module pitch (G) ² | 125 cm |

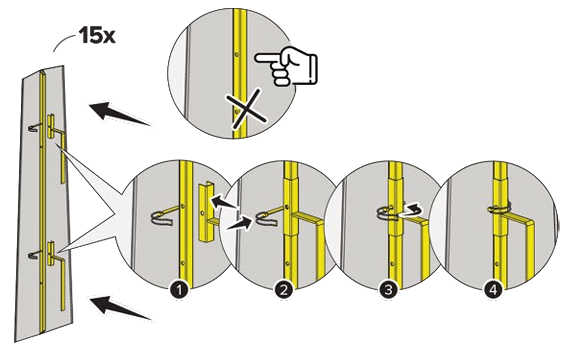

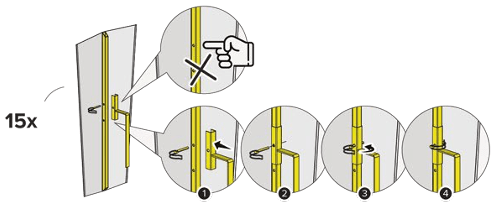

| Sealer clips | 15 |

¹ The included angle between the center planes of two adjacent corner modules (plan view).

² Center-to-center spacing between adjacent corner modules measured along the base chord (straight line between module centers).

| Turning radius | 485 cm |

| Top edge arc length (D) | 630 cm |

| Outer base arc (E) | 760 cm |

| Lower outer arc length (F) | 340 cm |

| Corner module splay angle (H) ¹ | 18° |

| Corner module pitch (H) ² | 70 cm |

| Membrane length | 630 cm |

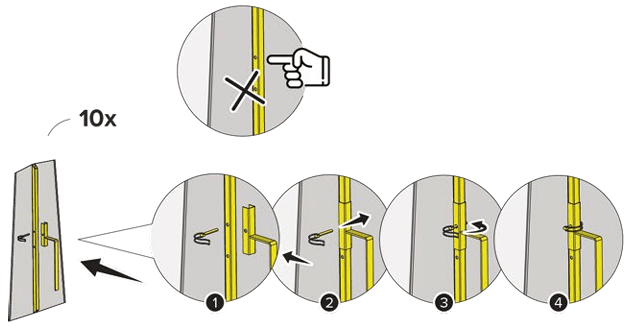

| Sealer clips | 15 |

¹ The included angle between the center planes of two adjacent corner modules (plan view), measured at the inner curve of the barrier.

² Center-to-center spacing between adjacent corner modules measured along the inner base chord (straight line between module centers).

| Material | High strength low alloy steel |

| Dimensions | L 223 x W 32 x D 7,6 cm |

| Weight | 40 kg |

| Quantity / module | 1 pc |

| Material | High strength steel |

| Dimensions | Min. L569 mm Max. L749 mm |

| Weight | 2,6 kg |

| Quantity / 90 degree OUTER corner | 5 pcs |

| Quantity / 90 degree INNER corner | 5 pcs |

| Material | High strength steel |

| Dimensions | min. L794 mm max. L1189 mm |

| Weight | 3,9 kg |

| Quantity / 90 degree OUTER corner | 10 pcs |

| Quantity / 90 degree INNER corner | 10 pcs |

| Material | Zinc coated, galvanized steel |

| Dimensions | L 179 x W 53/38 cm |

| Weight | 12 kg |

| Quantity / 90 degree OUTER corner | 15 pcs |

| Quantity / 90 degree INNER corner | 10 pcs |

| Material | Zinc coated, galvanized steel |

| Dimensions | L 100 x W 50/37 cm |

| Weight | 7 kg |

| Quantity / 90 degree OUTER corner | 10 pcs |

| Quantity / 90 degree INNER corner | 15 pcs |

| Material | Laminated high density polyethylene |

| Dimensions | L 50 x W 7 m - 140 g/m2 |

| Weight | 48,5 kg per roll |

| Quantity / 90 degree OUTER corner | 12,4 m / 0,248 roll |

| Quantity / 90 degree INNER corner | xxxx |

| Material | Galvanized steel DIN766 |

| Dimensions | L 5 m x 12 mm links excluding carabiners |

| Weight | 15.6 kg |

| Quantity / 90 degree OUTER corner | 17,9 m |

| Quantity / 90 degree INNER corner | 10 m |

| Material | Nylon |

| Dimensions | L 38 cm |

| Weight | 0.001 kg |

| Quantity / 90 degree OUTER corner | 25 pcs |

| Quantity / 90 degree INNER corner | xxx |

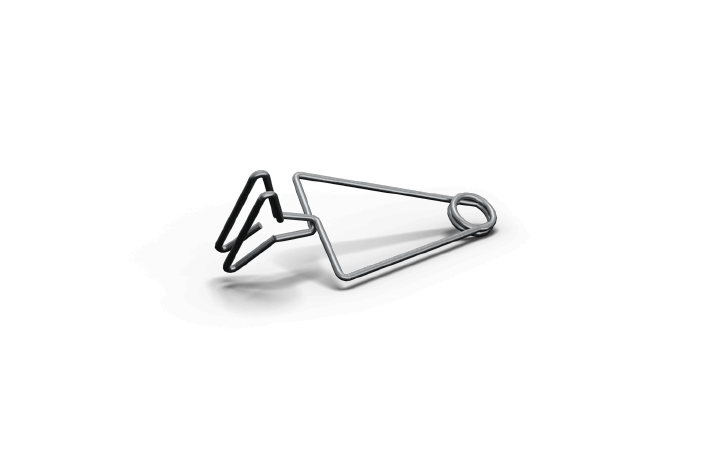

| Material | Steel |

| Dimensions | L 17 cm |

| Weight | 0,08 kg |

| Quantity / 90 degree OUTER corner | 10 pcs |

| Quantity / 90 degree INNER corner | 15 pcs |

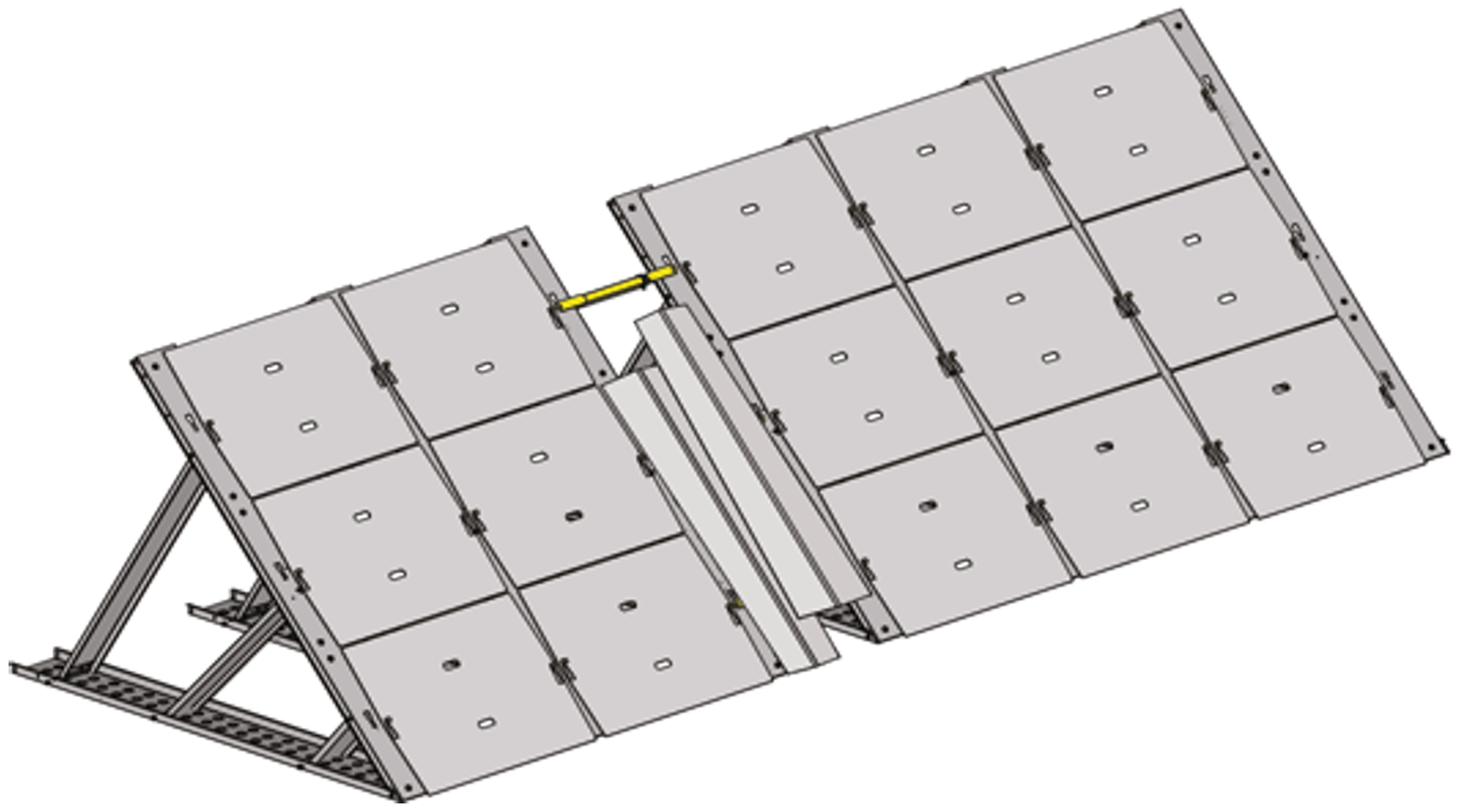

Our step-by-step setup manual provides clear, visual instructions to help you assemble the C184 Heavy Duty flood barrier quickly and confidently. Whether you’re new to the system or an experienced operator, the guide walks you through each stage

While the C184 can be set up without tools or machinery, we recommend hands-on training and consultation for optimal results. These additional resources ensure correct installation, improved efficiency, and reliable long-term performance in demanding flood conditions

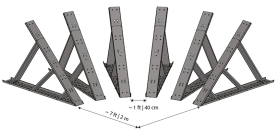

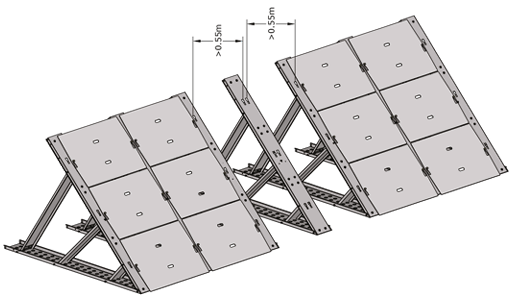

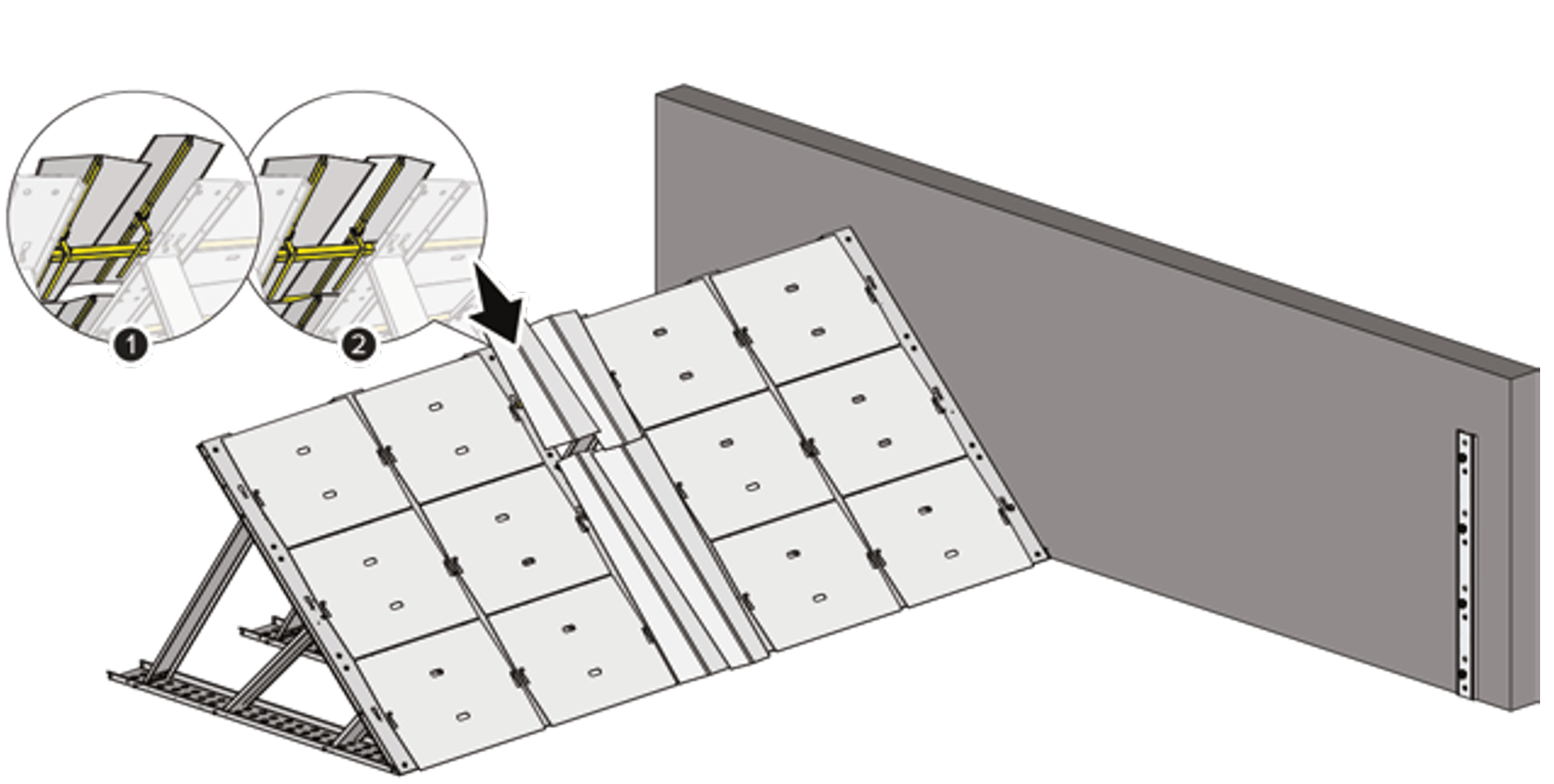

Place the C72 | C184 barrier supports 4 ft | 122 cm apart. Use link bars to gauge the distance.

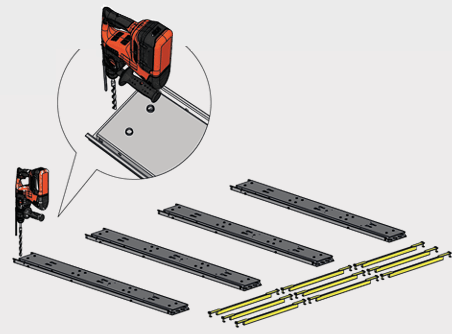

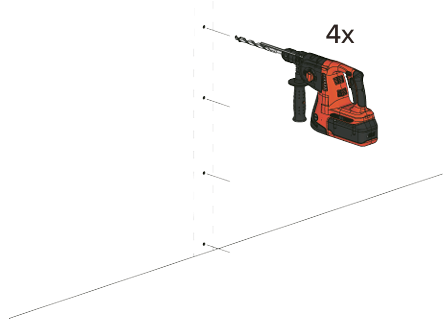

If installed on concrete

Prepare installation of concrete anchor. Drill a hole using a hammer drill.

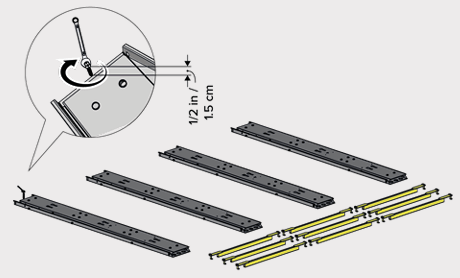

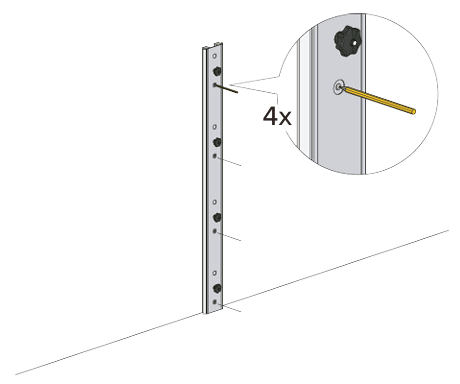

If installed on concrete

Screw on the concrete anchors into the ground. Leave a distance of 1/2 in / 1.5 cm between top of the concrete anchor and the bottom beam of the C72 | C184 barrier supports.

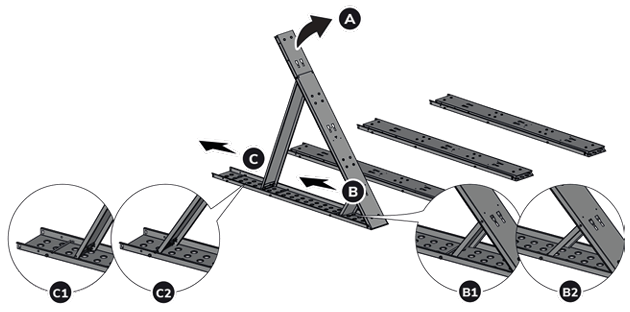

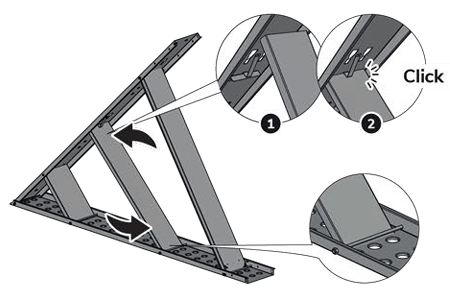

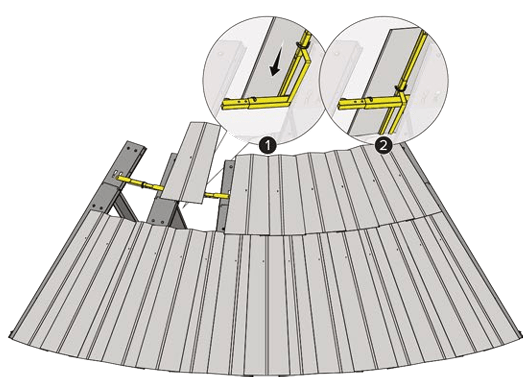

Erect the C72 | C184 barrier supports. Lift the front beam up and unfold the support beams.

Secure the C72 | C184 Barrier supports upright position with the Snap lock.

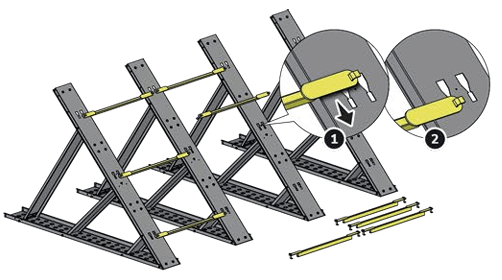

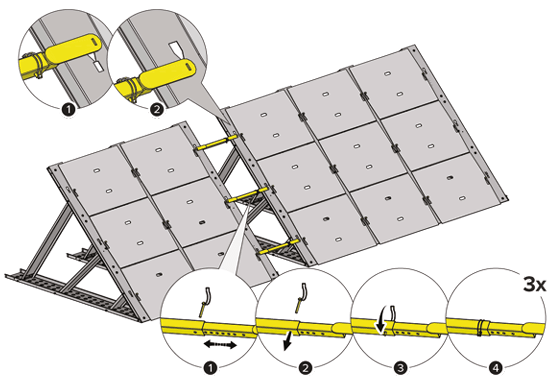

Connect the C72 | C184 barrier supports using link bar.

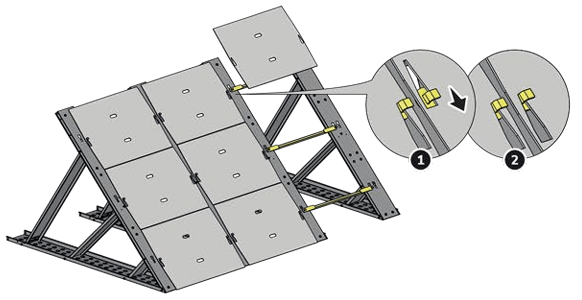

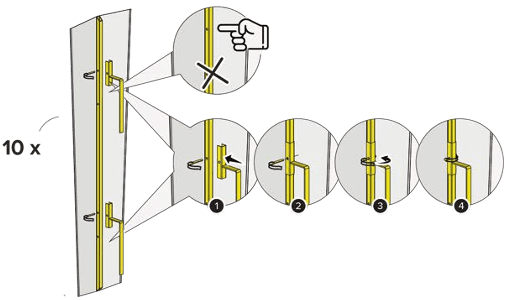

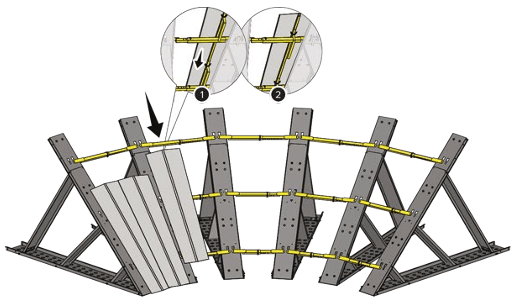

Mount the 860 aluminum panels by sliding the key hole cut out over the protruding part of the link bar.

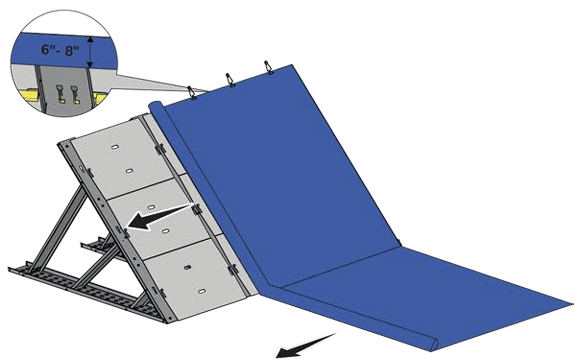

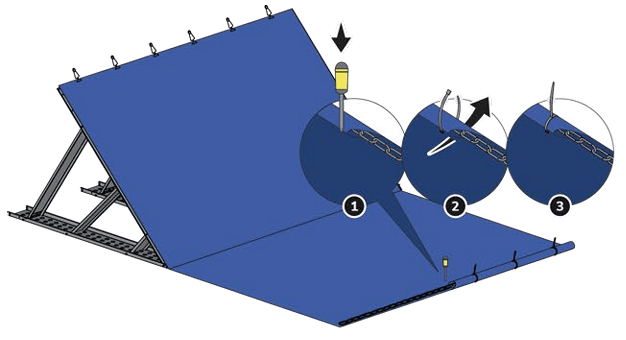

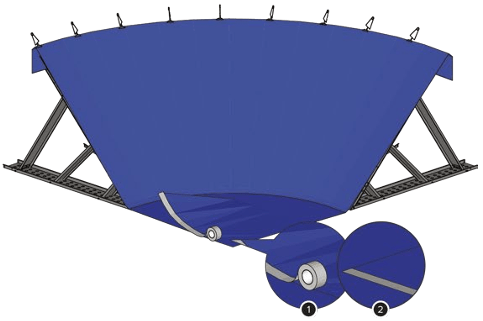

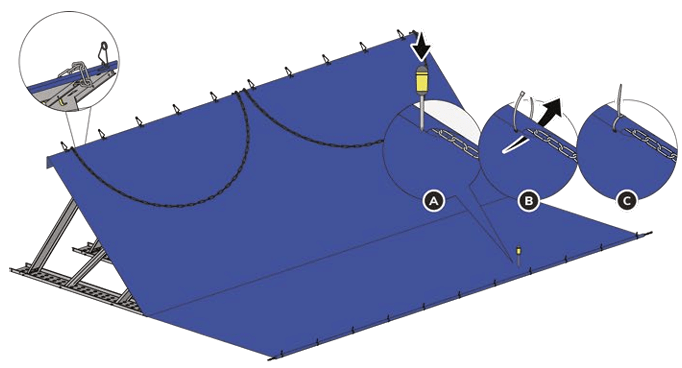

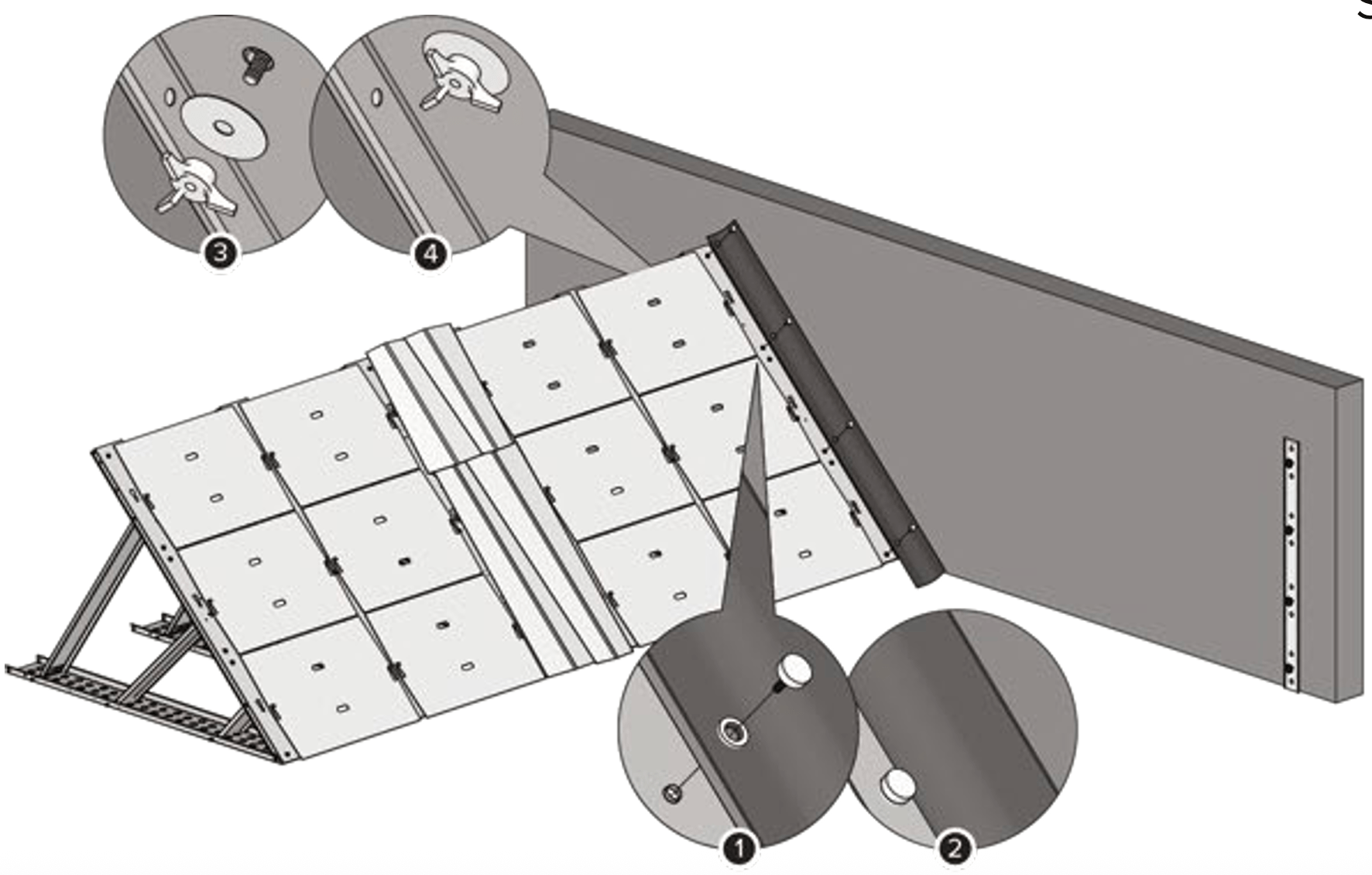

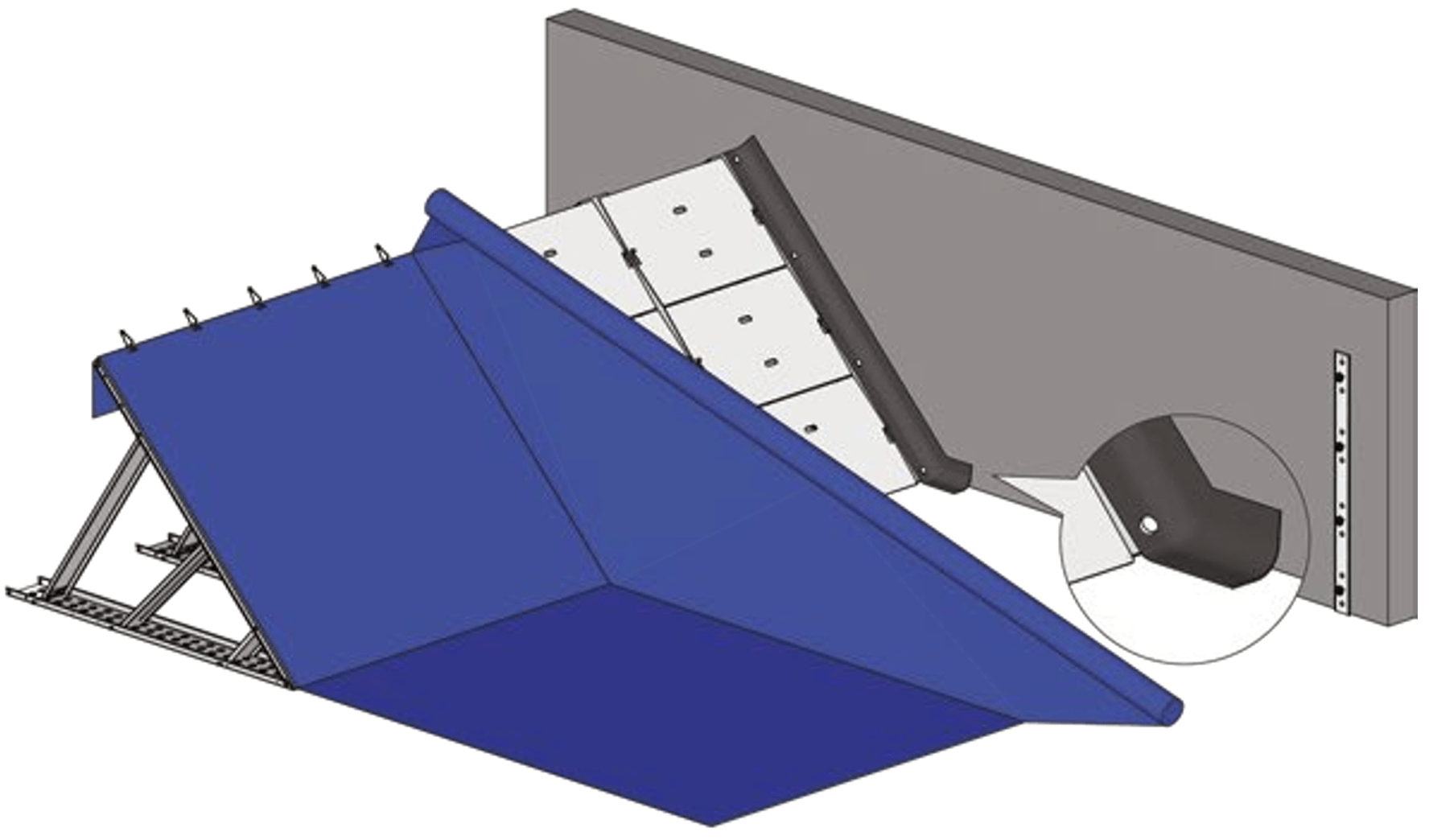

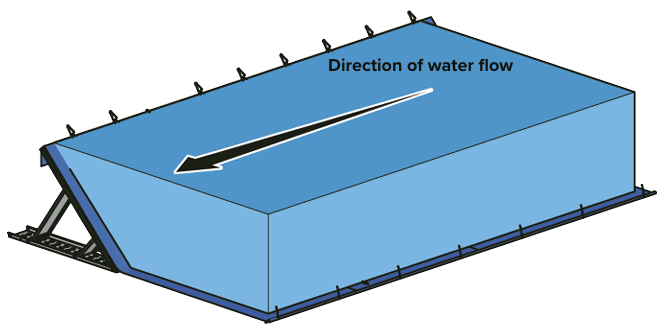

Roll out the poly membrane and secure with two sealer clip per section, along the top edge. Ensure that there is between 6-8 in | 15-20 cm overlap at the back of the barrier.

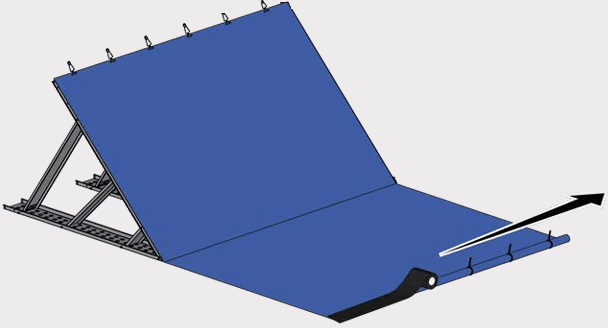

Connect the chain lengths with the karabiners and place it along the outer edge of the poly membrane. Wrap the chain in the poly membrane and secure with cable ties.

If installed on concrete

Seal the poly membrane to the ground using 8 in / 20 cm wide sealing tape.

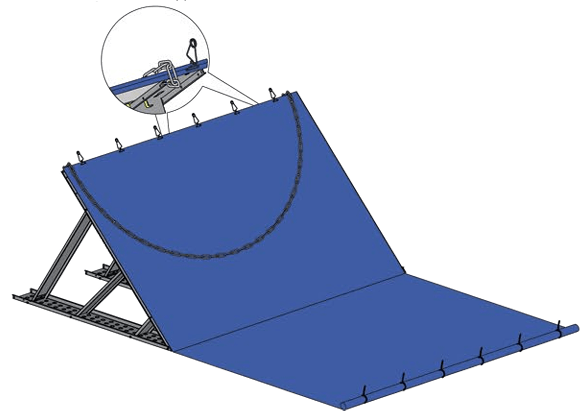

Hang the garland chain on to the inclined part of the barriers. Use the carabiner hook to secure the chain to the C72 | C184 barrier supports.

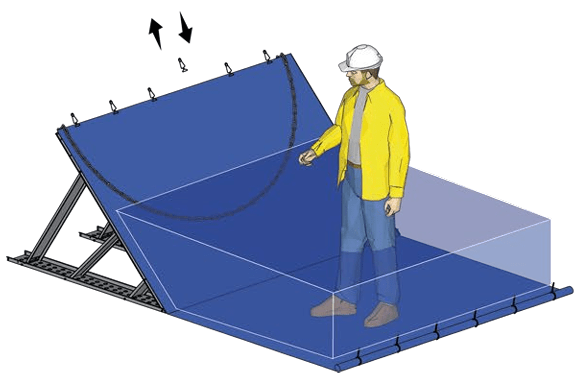

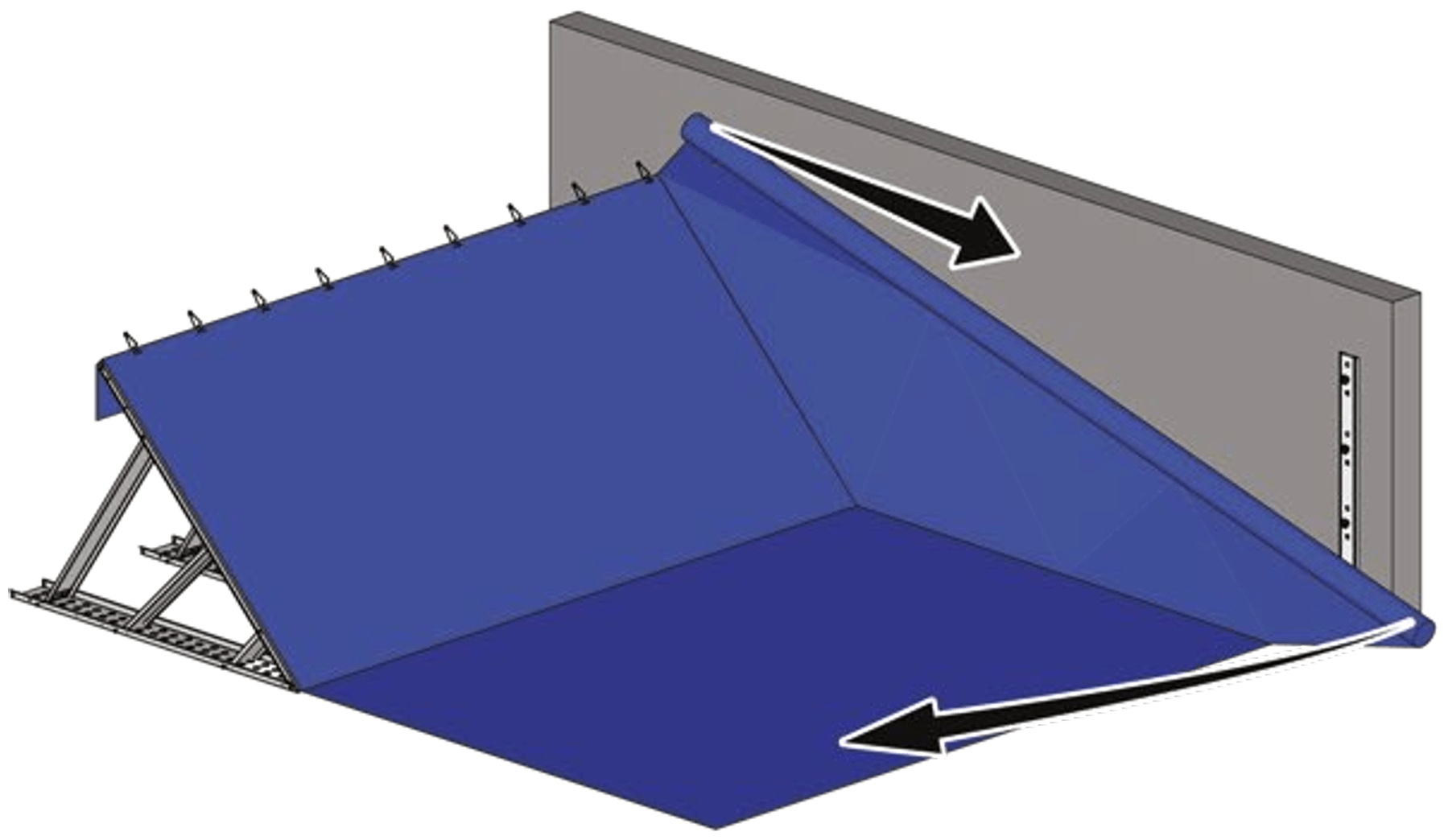

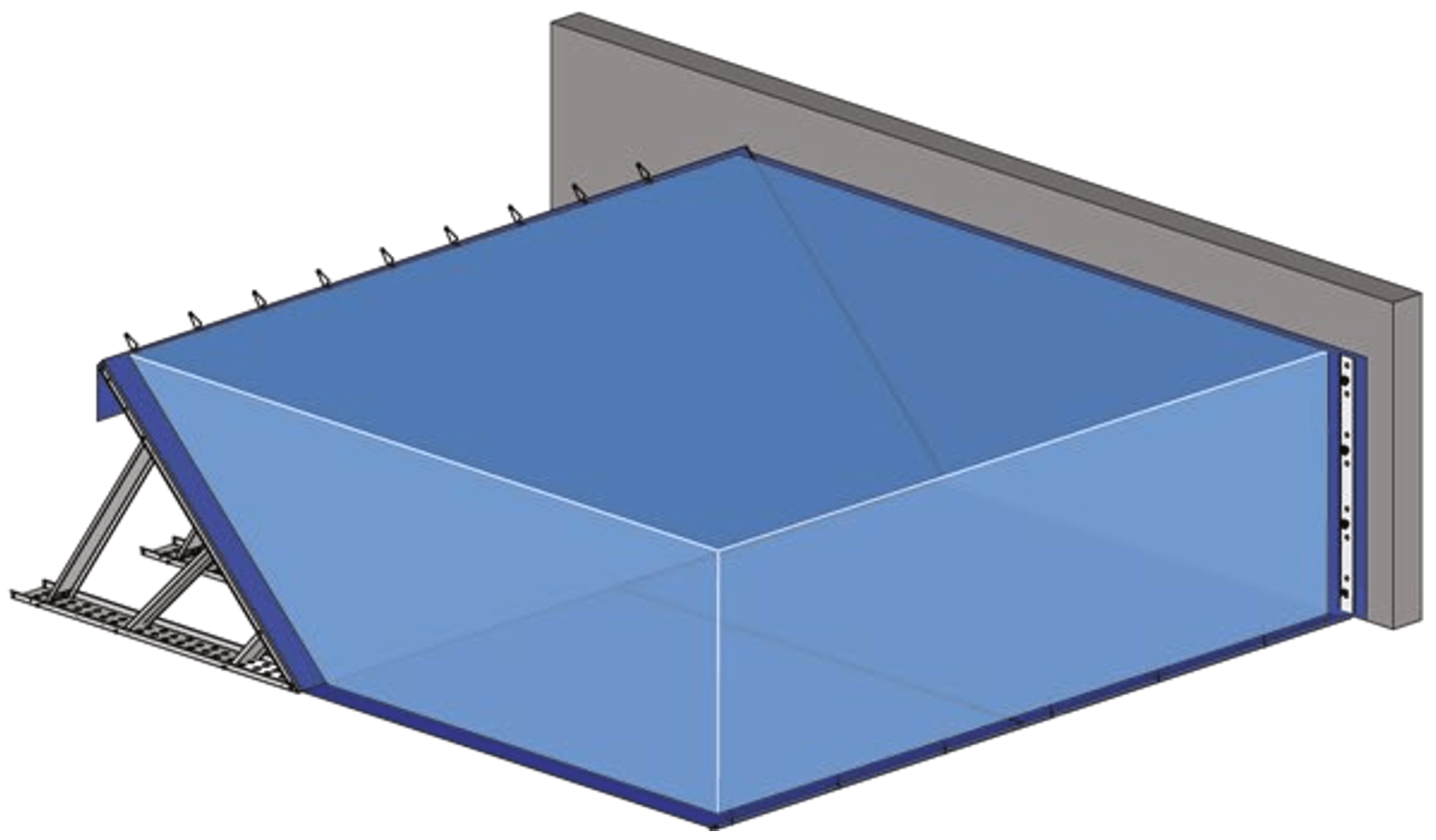

Adjust sealer clips when the water enters the barrier to relax the poly membrane. Squeeze out air pockets under the poly membrane by gently stepping on them.

Installed and self-anchored as rising water presses the barriers to the ground.

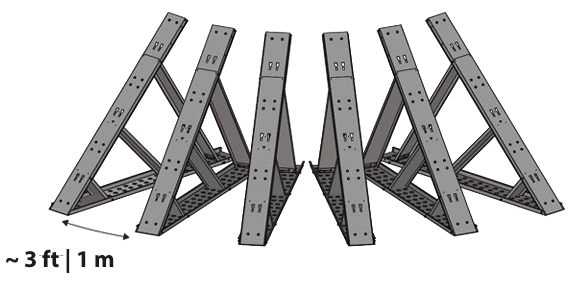

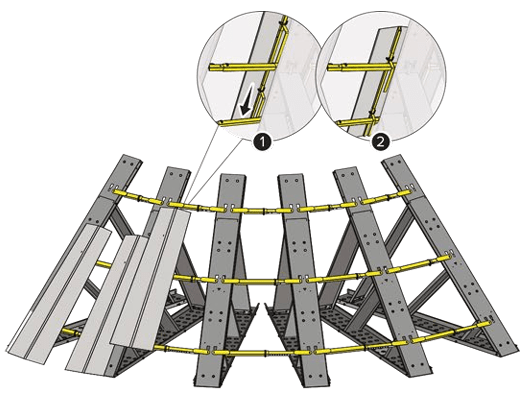

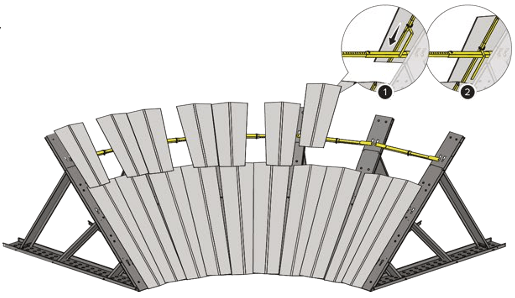

Place six unfolded and secured C72 | C184 Metal Supports in a 90° arc approx 3.3 ft | 1 m apart.

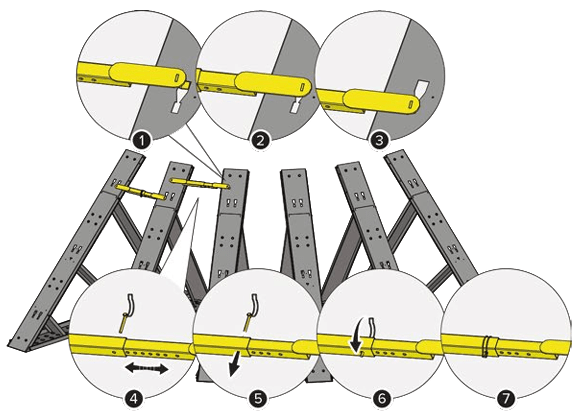

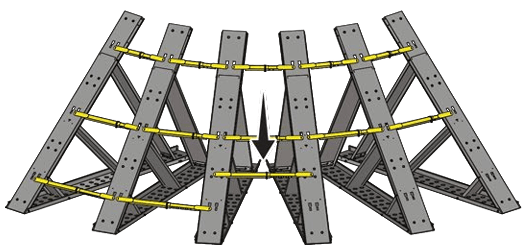

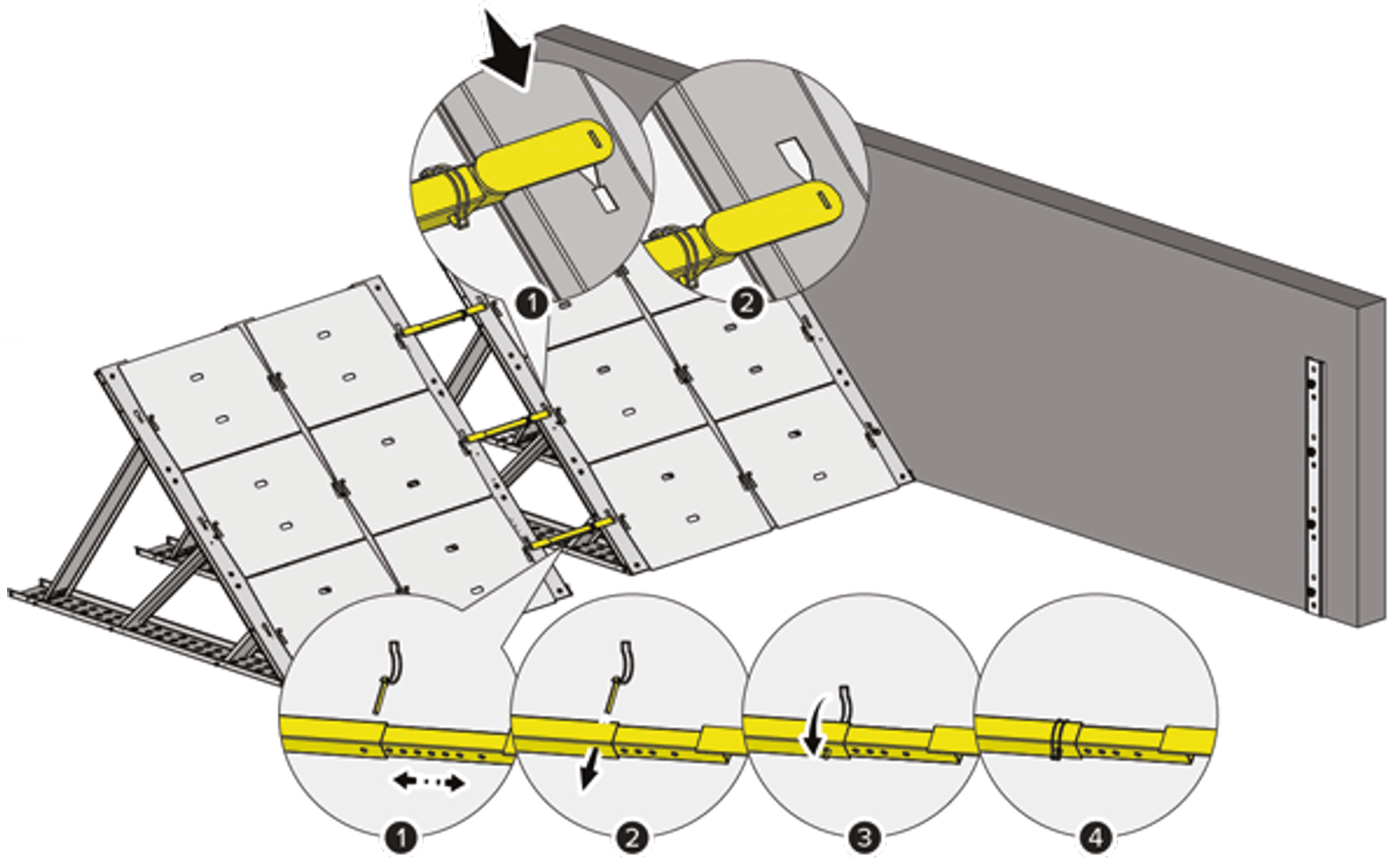

Begin connecting the C72 | C184 Metal Supports using Adjustable Connection Rods SMALL (ACR-Small). Insert the ACR-Small through the top keyhole cuts on the C72 | C184 Metal Supports and slide down to lock. Fix each ACR-Small at a suitable length with the Pin Lock

Continue connecting the C72 | C184 Metal Supports by attaching the Adjustable Connection Rods LARGE (ACR-Large) through the middle and bottom keyhole cuts and slide down to lock. Fix each ACR-Large at a suitable length with the Pin Lock.

Assemble the Corner Element LARGE (CE-Large). The wide part of the CE-Large should face downwards. Attach the handles to the top holes of the CE-Large. Fix using the Pin Lock.

Place two CE-Large onto the middle and lower ACR. Slide them down into position – one to the left and one to the right. Leave a gap in between.

Fill the gap by sliding a third CE-Large on top of the other two.

Assemble the Corner Element SMALL (CE-Small). The wide part of the CE-Small should face downwards. Attach the handle to the top hole on the CE-Small. Fix using the Pin Lock.

Place the CE-Small onto the top ACR. Slide down into position. Use two CE-Small per section.

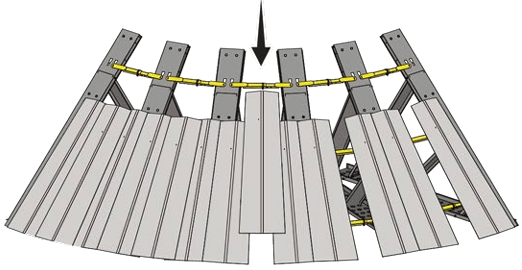

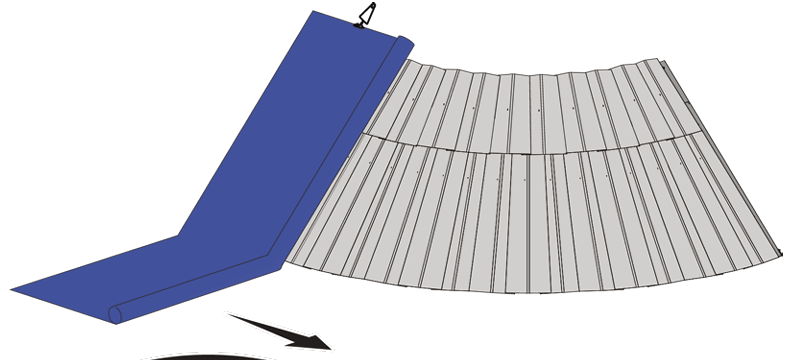

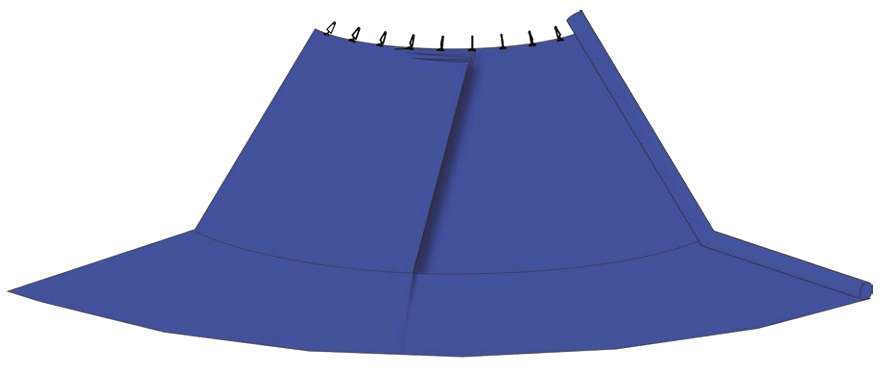

Start rolling out the membrane from the beginning of the arc. Fold membrane over the top by max 10 in | 25 cm. Fix the membrane to the C72 | C184 outer corner with Sealer Clips at the top.

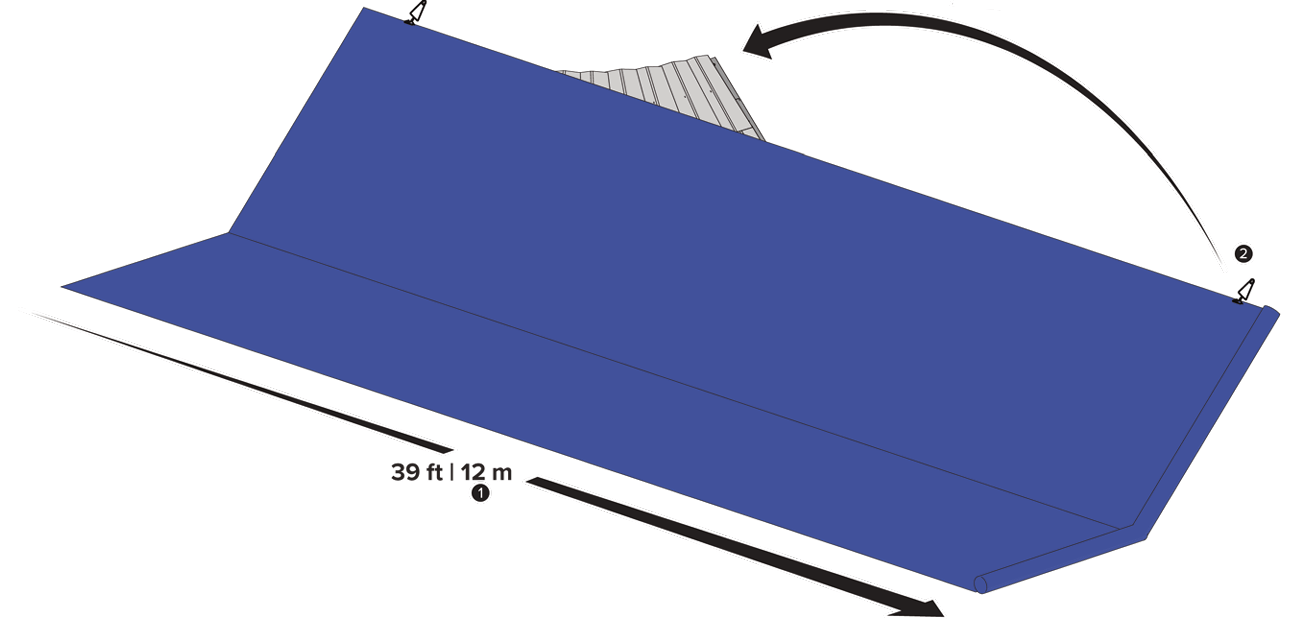

Extend the membrane 39 ft | 12 m out from the C72 | C184 outer corner. Fold the extended membrane back.

Seal the folded plastic membrane to the barrier with Sealer Clips. Add loading chain to the outer edge according to instructions in the standard manual.

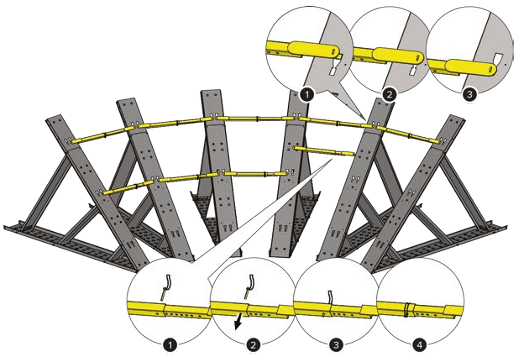

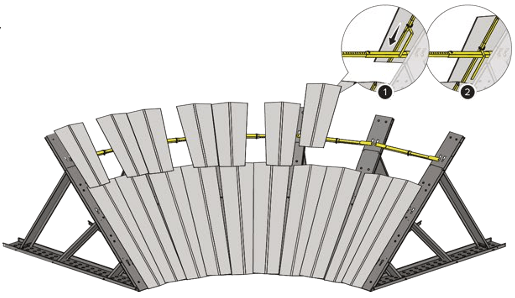

Place six unfolded and secured C72 | C184 Metal Supports in a 90° arc, approximately 1 ft | 0.4 m apart. The outermost supports should be at a 90 degree angle to each other.

Begin connecting the C72 | C184 Metal Supports using adjustable Connection Rod LARGE (ACR-Large). Attach the ACR-Large through the top keyhole cuts on the C72 | C184 Metal Supports and slide down to lock. Fix each ACR-Large at a suitable length with the Pin Lock.

Continue connecting the C72 | C184 Metal Supports by attaching the Adjustable Connection Rods SMALL (ACR-Small) through the bottom keyhole cuts and slide down to lock. Fix each ACR-Small at a suitable length with the Pin Lock.

Assemble the Corner Element LARGE (CE-Large). The wide part of the CE-Large should face upwards. Attach the handles to the top holes of the CE-Large. Fix using the Pin Lock.

Place two CE-Large onto the middle and lower ACR. Slide them down into position – one to the left and one to the right.

Assemble the Corner Element SMALL (CE-Small). The wide part of the CE-Large should face upwards. Attach the handles to the top holes of the CE-Large. Fix using the Pin Lock.

Place two CE-Small onto the top ACR. Slide them down into position – one to the left and one to the right. Leave a gap in between.

Fill the gap by sliding a third CE-Small on top of the other two.

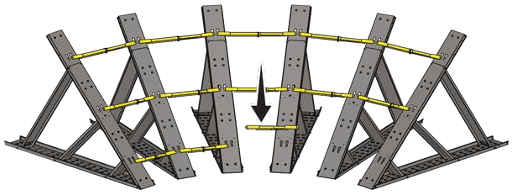

Fix the position of the membrane to the C72 | C184 inner corner with a Sealer Clip. Start rolling out the membrane from the beginning of the arc. Fold membrane over the top by max 10 in | 25 cm. Rotate the membrane roll 90° to cover the inner corner.

Fix the membrane with two sealer clips per section – in total 9 clips for the whole corner – along the top edge. Fold the surplus plastic membrane neatly and close any openings using duct tape.

Installed!

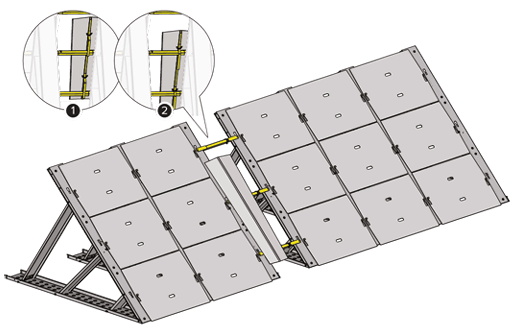

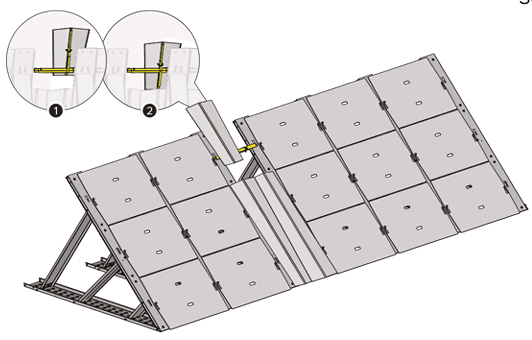

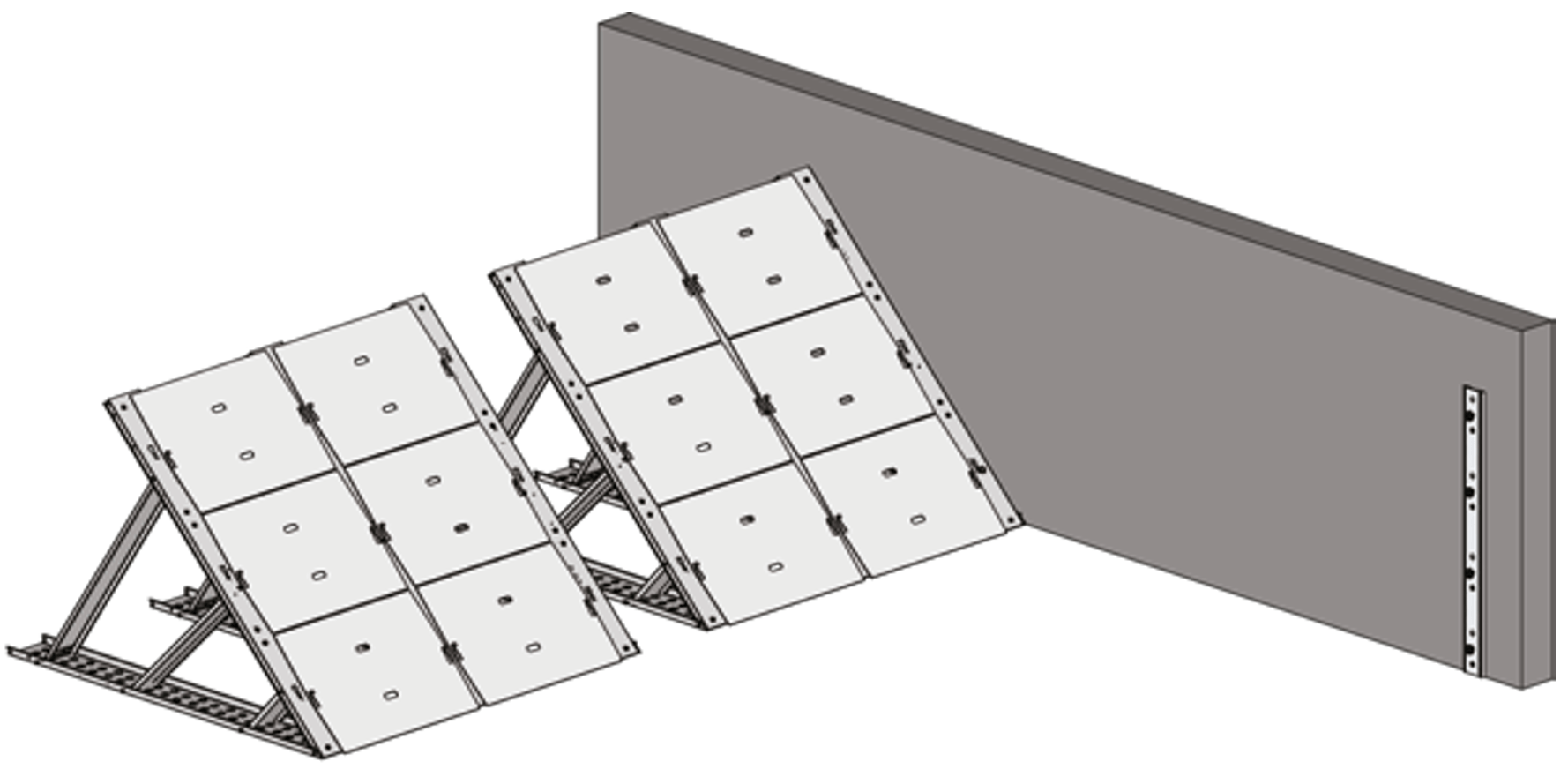

Build the two approaching C72 | C184 barriers in a line. Stop when the distance between the barriers is smaller than one full section (48 in | 1.22 m).

If the distance in the previous step is smaller than 21.65 in | 0.55 m, remove one full section. Then create two adjustable sections with equal widths.

Use adjustable Connection Rods (ACR) to patch the section or sections where the two barrier lines meet. Use SMALL or LARGE ACR depending on the distance of the adjustable section or sections.

Assemble the Corner Element LARGE (CE-Large). The narrow part of the CE-Large should face downwards. Attach the handles to the top holes of the CE-Large. Fix using the Pin Locks.

Start covering the adjustable section with the CE-Large. Slide it down into position on the middle and lower ACR with the wide part up.

Assemble another CE-Large. This time make the wide part of the CE-Large face downwards. Attach the handles to the top holes of the CE-Large. Fix using the Pin Locks.

Continue to cover the adjustable section with the CE-Large. Slide it down into position on the middle and lower ACR with the narrow part up. Continue in the same way by alternating the direction of the CE-Small up and down if additional Corner Elements are needed.

Assemble the Corner Element SMALL (CE-Small). The narrow part of the CE-Small should face downwards. Attach the handles to the top holes of the CE-Small. Fix using the Pin Locks.

Begin covering the top part of the adjustable section with the CE-Small. Slide it down into position on the top ACR with the wide part up.

Assemble another (CE-Small). The wide part of the CE-Small should face downwards. Attach the handles to the top holes of the CE-Small. Fix using the Pin Locks.

Close the section by placing the second CE-Small on the top ACR with the narrow part up and slide down in to position. Continue in the same way by alternating the direction of the CE-Small up and down if additional Corner Elements are needed.

Cover the barrier with the Poly Membrane

Fix the GB Membrane with Sealer Clips. Add chain lengths with connecting karabiners along the outer edge. Instructions for enclosing the chain can be found in the manual for C72 | C184 Classic Straight Sections.

Installed!

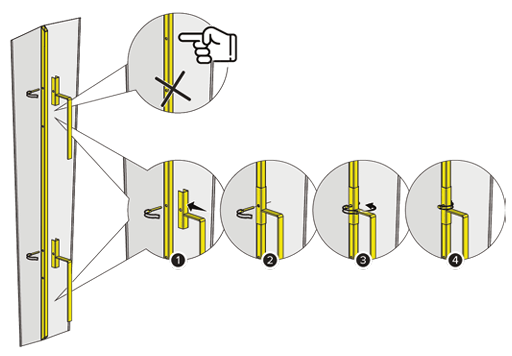

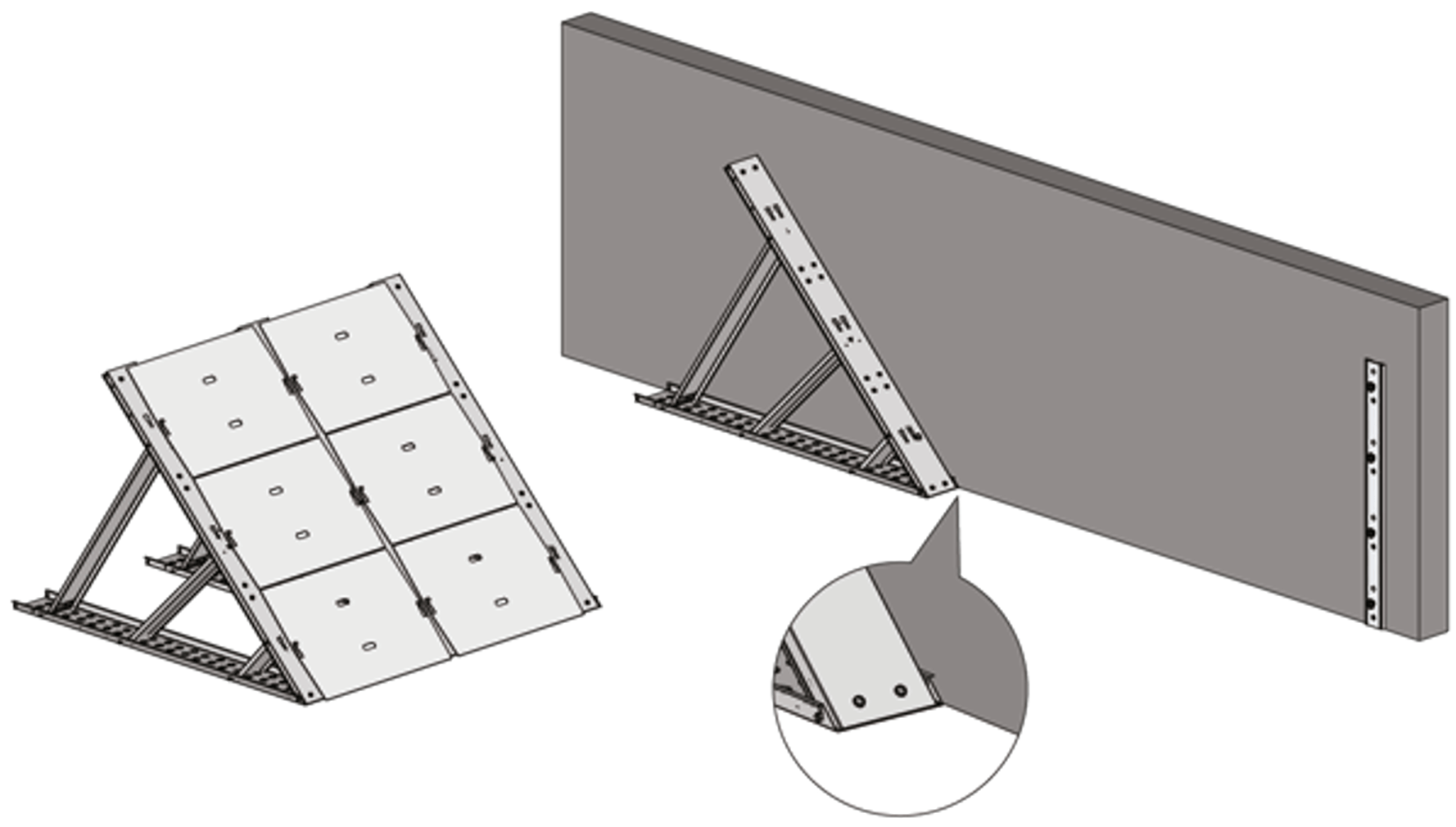

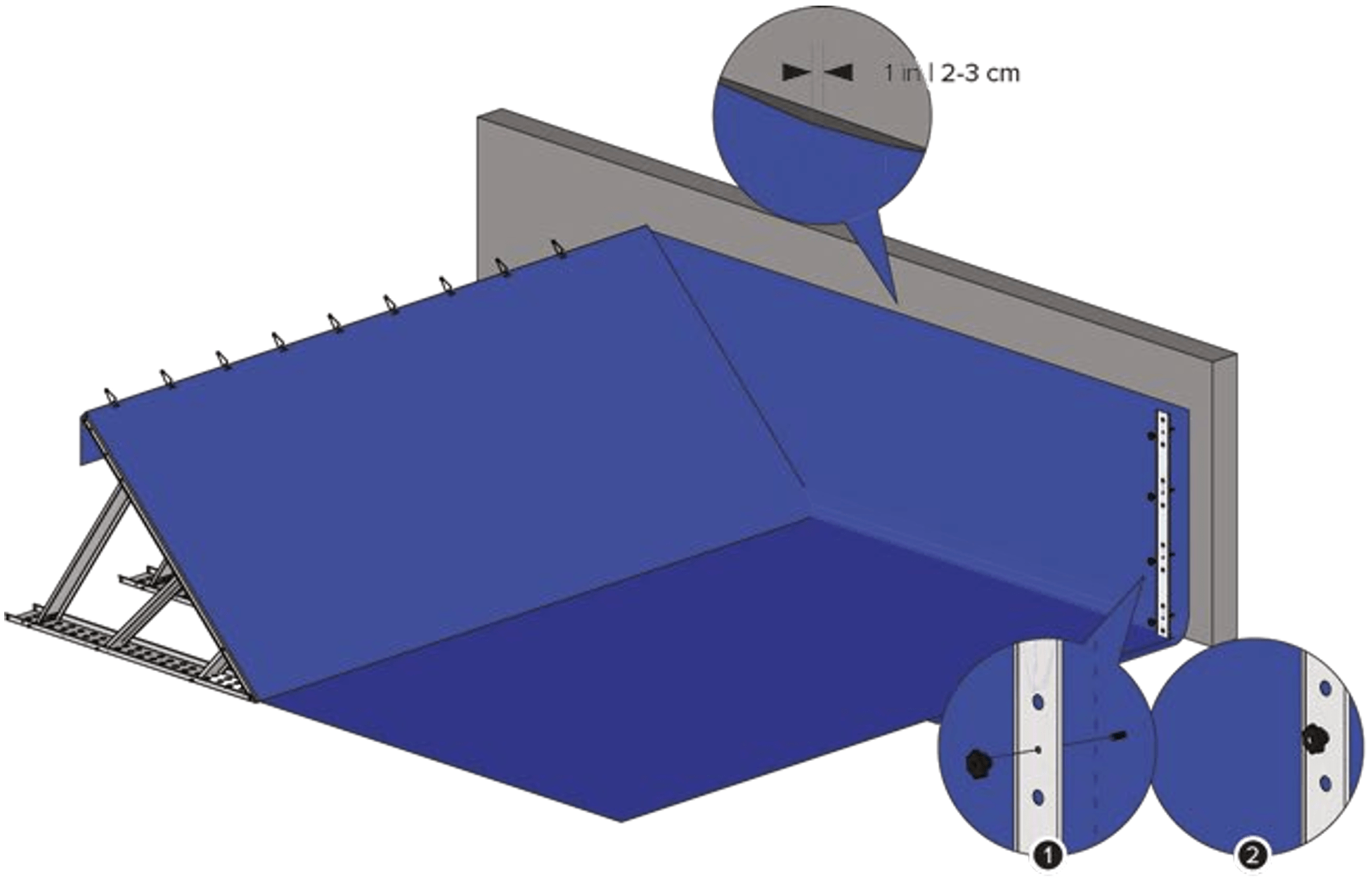

As the barrier line approaches the wall, stop at a distance of a few sections' lengths from the wall. Place the support in line with the barrier, parallel to the wall, as close to it as possible.

Start assembling the barrier from the wall towards the already assembled barrier leading up to the wall.

Patch the section where the two barrier lines meet using adjustable connection rods (ACR). Attach ACRs through keyhole cut on the front beam and slide down to lock. Fix and adapt the ACRs to suitable lengths using their D-clips.

Start covering the adjustable section with Corner Elements. Place them onto the ACR. Slide them down into position (one up, one down) ensuring the handles hook onto the ACRs. More detailed instructions can be found in the "C72 | C184 Adjustable section - Setup manual”.

Mount the Wall Connection Pad to the front of the C72 | C184 support to bridge the gap to the wall. Align the holes in the pad with the round collared holes on the support and secure with the four armed wing nuts.

Align the bottom part of the wall connection pad to the ground. Roll out the 23 ft | 7.0 m membrane over the barrier and secure with two sealer clips per section, along the top edge. Ensure that there is 8 - 10 in | 20 - 25 cm overlap at the back of the barrier.

Continue to cover the barrier. Stop close to the wall. Make a 90 degree turn with the membrane to cover the the wall.

Make sure the membrane covers the wall all the way to the previously attached 72 | 184 Wall batten.

Give the membrane some slack, leaving a 1 in | 2-3 cm gap to the wall. Remove the front plate from the 72 | 184 Wall batten and feed the membrane in – sandwiched between the two plates. Put the front plate back, puncture the membrane and lock with the screws.

Use duct tape to seal the open parts of the membrane. Place the chain on the outer edge of the membrane and wrap it. Secure the embedded chain using cable ties – one every metre. More detailed instructions can be found in the "C72 | C184 Straight sections - Setup manual”.

Installed!

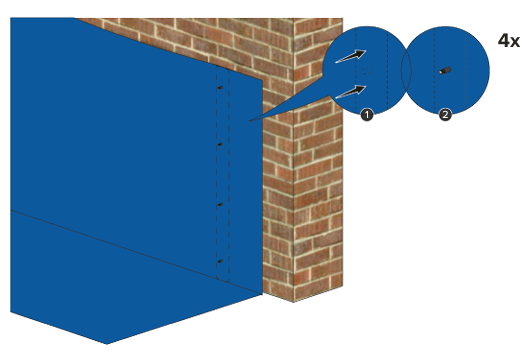

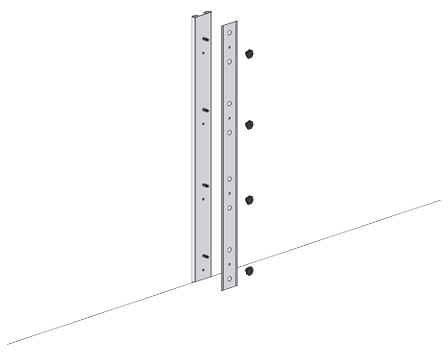

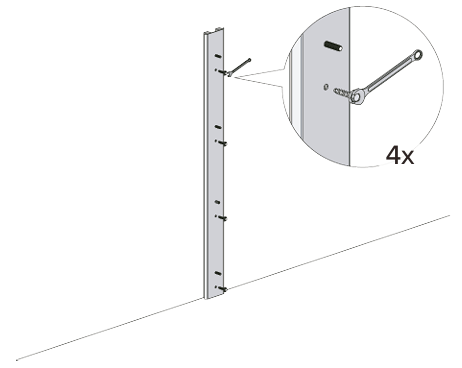

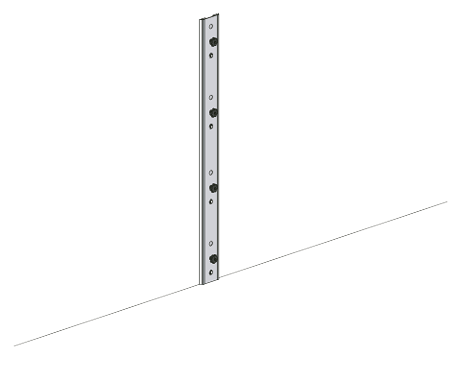

Hold the Wall Batten up against the wall in the desired position.

Use a pen to make markings on the wall where the holes in the Wall Batten are located.

Drill holes in the wall and install suitable anchors.

Unscrew the 4 tightening knobs and remove the top plate from the Wall Batten.

Mount the base batten to the pre drilled holes in the wall using appropriate screws, washers, nuts and bolts to your specific wall.

Put the top plate and the 4 tightening knobs back. Wall Batten installed.

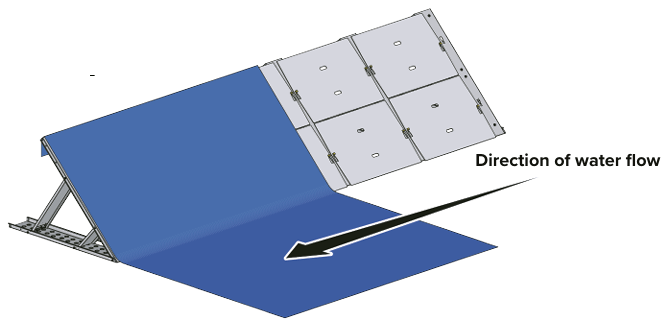

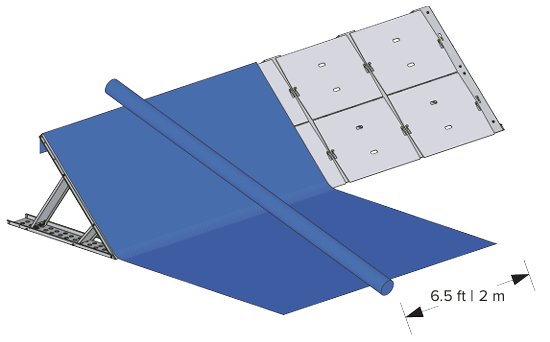

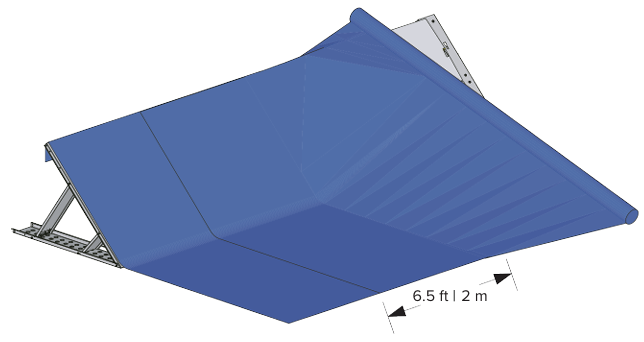

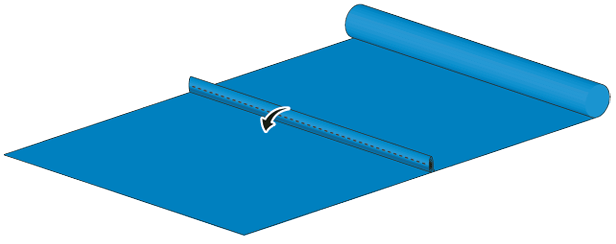

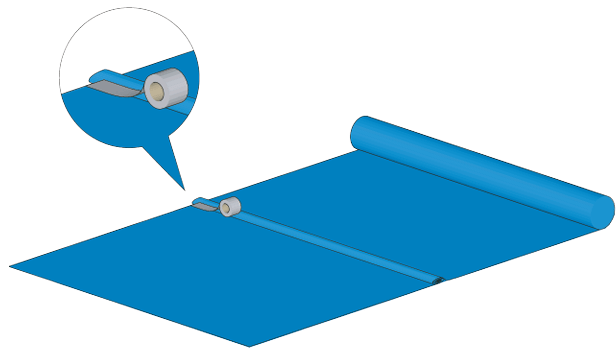

Roll out the the previous Poly Membrane completely.

Start to roll out the new Poly Membrane in the same direction. The two membranes should overlap with at least 6.5 ft | 2 m.

Continue to roll out the Poly Membrane. Make sure the overlap stays 6.5 ft | 2m.

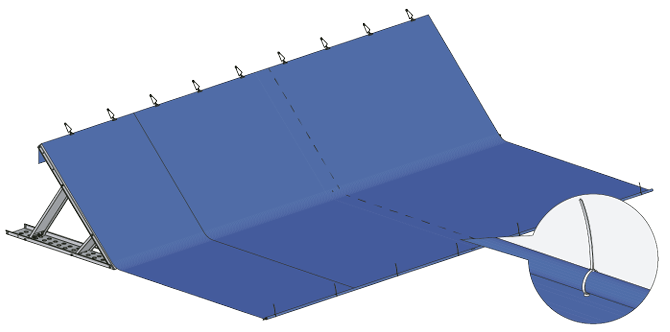

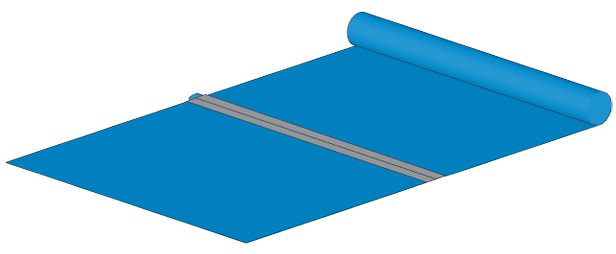

Place Sealer Clips at the top edge of the barrier. Place the Chain on the outer edge of the Poly Membrane and wrap it. Secure the embedded Chain using Cable Ties – one every 3 ft | 1 m. More detailed instructions can be found in the Setup Manual for straight sections.

Place a vertical loading chain at the beginning of the new Poly Membrane to keep it down. Hang it on to the top edge of the barrier using the carabiner.

Installed!

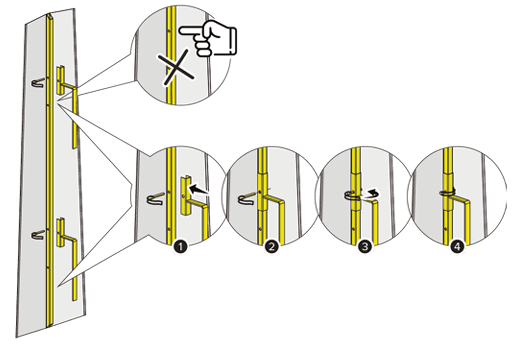

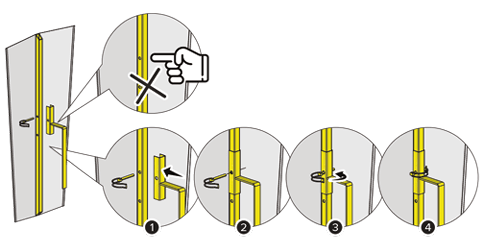

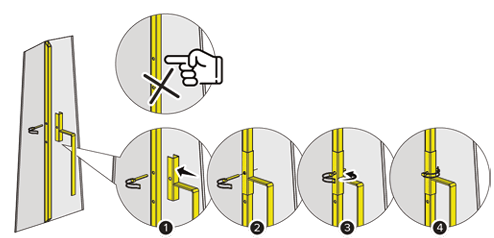

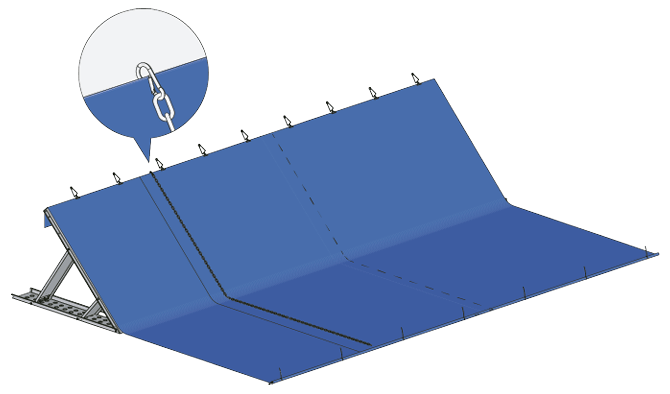

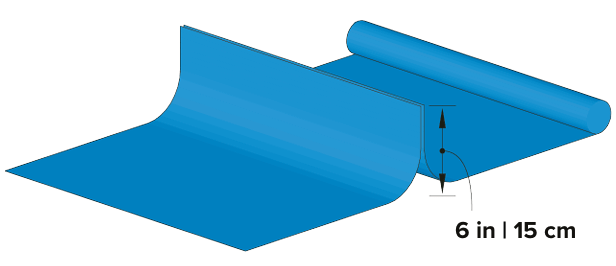

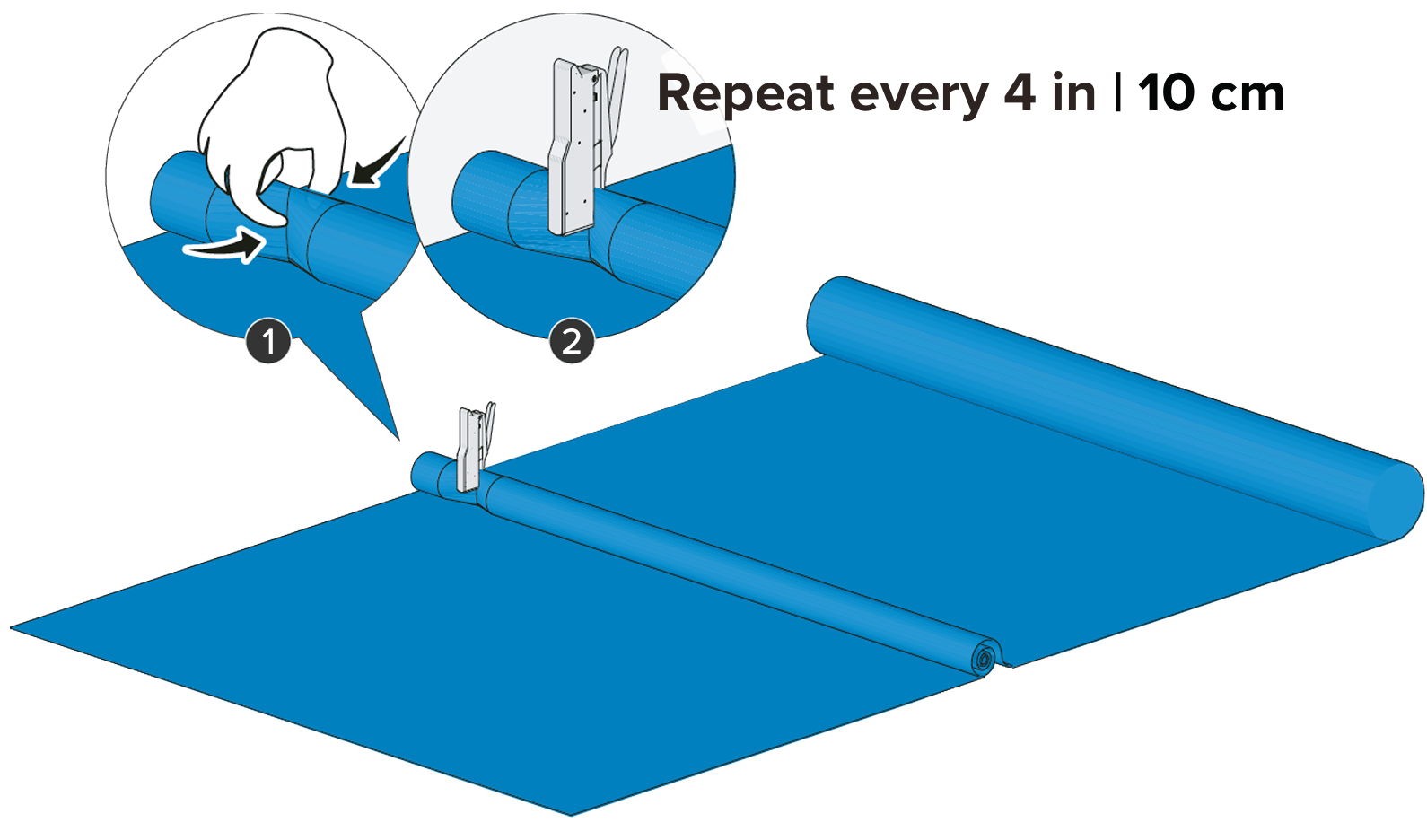

Lift up the ends of both Poly Membranes approximately 6 in | 15 cm.

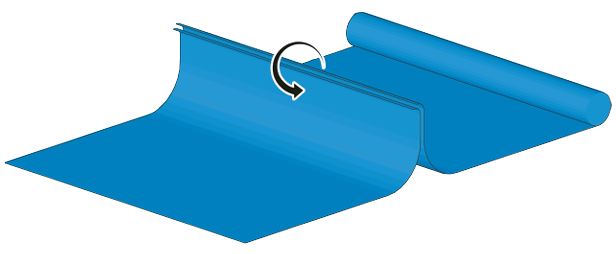

Hold the membranes together and align the edges. Seam the membranes by rolling them down.

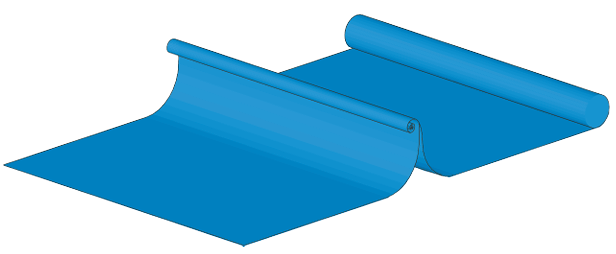

Continue creating a roll. Make it as tight as possible.

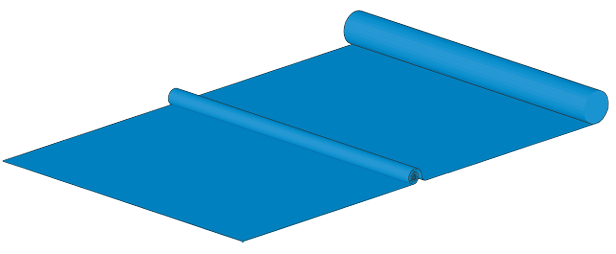

Roll it all the way down to the ground.

Pinch the roll with your fingers. Slide the stapler around it and staple the roll together. Repeat every 4 in | 10 cm along the roll.

Optional: Fold down the stapled roll.

Optional: Tape the roll down to minimize seepage. Tape a second parallel line if necessary.

Done!

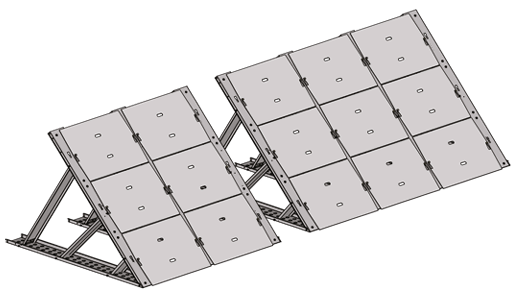

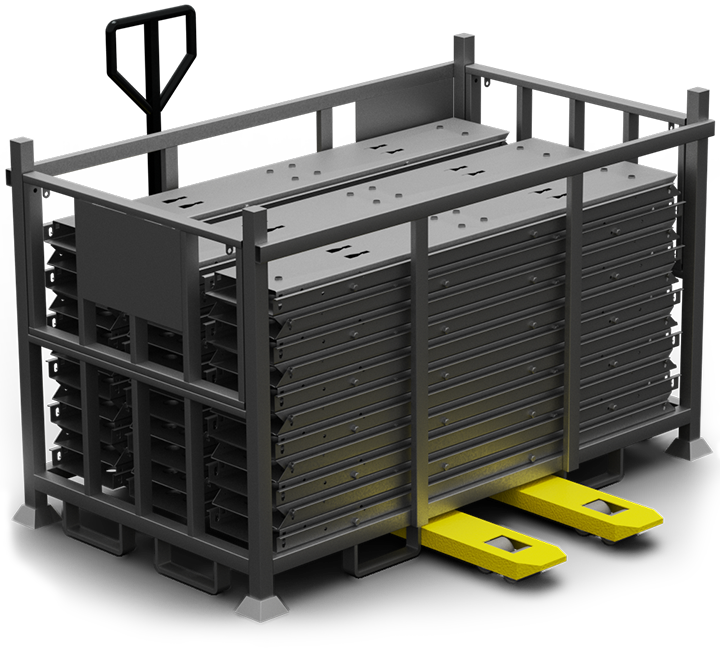

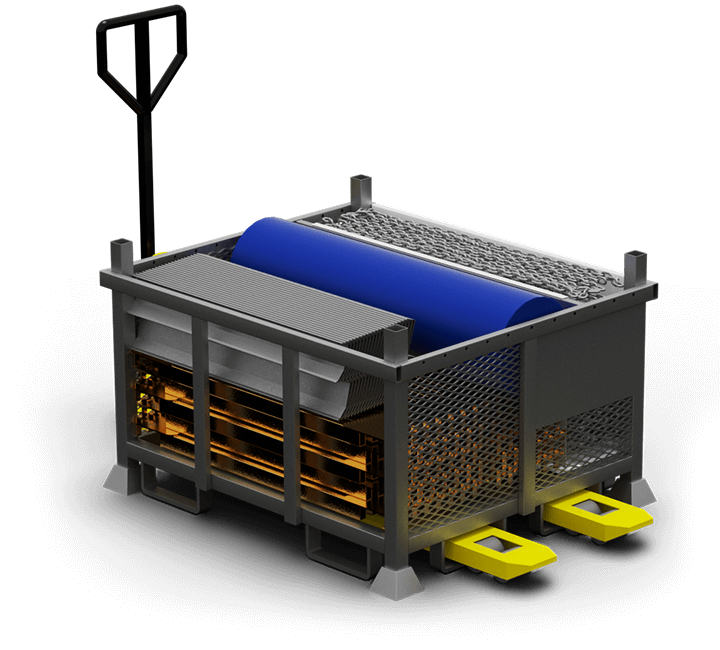

The C184 Heavy Duty System is shipped in durable, weatherproof metal crates designed for both transport and long-term storage. Each crate is fitted with a PVC hood to keep the contents dry and free from dust. These stackable crates allow for space-efficient storage and can be easily moved using a manual or electric forklift, providing flexible handling on-site.

| Material | Galvanized steel |

| Dimensions | L 1,4 x W 1,15 x H 0,88 m |

| Weight | 1189 kg |

| Quantity / crate |

80 alu panels |

| Material | Galvanized steel |

| Dimensions | L 2,9 x W 1,15 x H 1,1 m |

| Weight | 1415 kg |

| Quantity / crate |

33 supports |

| Material | Galvanized steel |

| Dimensions | L 1,4 x W 1,15 x H 0,88 m |

| Weight | 750 kg |

| Quantity / crate |

Remaining components |

The C184 Heavy Duty System is smartly organized in robust, stackable metal crates that fit perfectly inside a single 20-foot container. This space-efficient packaging allows for easy storage, strategic positioning, and rapid deployment — ensuring full-scale flood protection is always ready when and where it’s needed.

| Multi Crate: | 14 units |

| Stackable: | |

| Weight per unit: |

| C152 support crate: | 9 units |

| Stackable: | |

| Weight per unit: |

| Total Net weight (barriers only) |

1 unit |

Discover how the C184 Heavy Duty Barrier can deliver reliable, large-scale flood protection.

Contact us today for expert advice and a customized quote tailored to your specific requirements.