The C122 is a model within our Heavy Duty product range, embodying the same stable, robust, and durable construction as the other flood barriers in the series. As the very first Heavy Duty model produced by Geodesign Barriers, the C122 has been at the core of our DNA, with over 20 years of proven use in the field. Its flexible design makes it particularly well-suited to handle complex and challenging flood protection scenarios where adaptability is key.

Dam height

122 cm

Section width

C/C

122 cm

Deployment time

(100 m / 6 people)

50 min

Footprint

(Barrier and membrane)

4.3 m

Introducing the C122 Heavy Duty flood barrier, the original model in our Heavy Duty series and the foundation of Geodesign Barriers’ innovative flood protection system. Like its successors, the C122 features a triangular metal support that folds out and connects via two rods. Aluminum sheets are suspended from the rods, and a laminate-coated high-density polyethylene membrane is draped over the structure to form a ground-sealing surface.

The C122—like all Geodesign Barriers—can be deployed without tools, machinery, or groundwork. Once water arrives, it pushes the barrier into the ground, making it entirely self-anchoring.

As the first Heavy Duty barrier we produced, the C122 has over 20 years of proven field use and remains a flexible, reliable solution for complex and demanding flood protection challenges. With its robust design and 122 cm dam height, it offers unmatched versatility for a wide range of scenarios.

| Barrier footprint without membrane (A) | 177 cm |

| Maximum Water Column / Dam height (B) | 122 cm |

| Section Width (C) | 122 cm |

| Inclined Length (D) |

174 cm |

| Aluminum sheet height (E) | 86 cm |

| Membrane ground length (F) | 256 cm |

| Membrane width (F+D+20 cm) | 450 cm |

| Installation footprint (A+F) | 433 cm |

| Maximum Water Column / Dam height (A) | 122 cm |

| Set up time 100 metres by 6 workers | 50 min |

| Certifications | FM Approval ANSI 2510-2020 |

| Section Weight | 66.5 kg |

| Water Flow Resistance | 4 m/s |

| Extendable | +15 cm or +60 cm to C184 |

| Factor of safety | 1.5 |

| Load / section | xx.xx kN |

| Material | High Strength low alloy steel |

| Dimensions | L177 x W32 x H6.5 cm |

| Weight | 23.4 kg |

| Quantity / section | 1 pc |

| Material | High-strength steel |

| Dimensions | L122 x W5 x D7 cm |

| Weight | 3 kg |

| Quantity / section | 2 pcs |

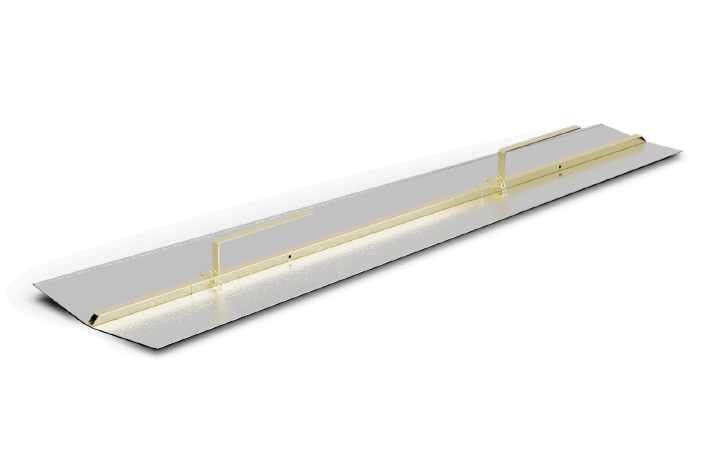

| Material | Aluminium Checker Plate |

| Dimensions | L120 x W86 x T0.7 cm |

| Weight | 13.7 kg |

| Quantity / section | 2 pcs |

| Material | PVC coated Low Density Polyethylene |

| Dimensions | L33 x W4.5 m - 420 g/m2 |

| Weight | 62 kg per roll |

| Quantity / section | 1.2 m / 0.037 roll |

| Material | Galvanized Steel DIN763 |

| Dimensions | L5 m x 12mm links excluding carabiners |

| Weight | 11.3 kg |

| Quantity / section | 3 m / 0.58 pcs |

| Material | Nylon |

| Dimensions | L38 cm |

| Weight | 0.001 kg |

| Quantity / section | 2 pcs |

| Material | High Strength low alloy steel |

| Dimensions | L97 x W12.5 cm |

| Weight | 3.75 kg |

| Quantity / section | 1 pc |

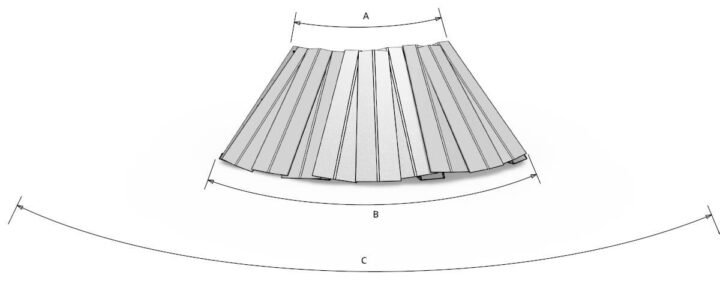

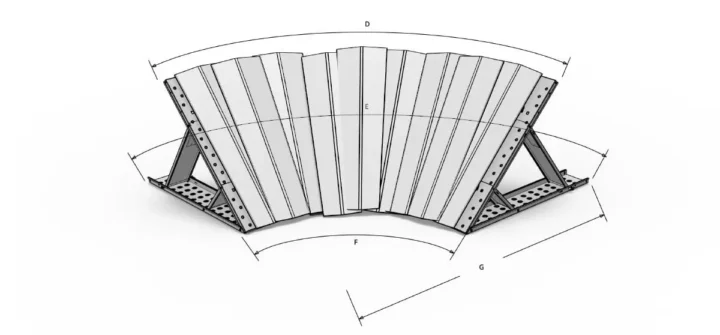

The C122 Heavy Duty flood barrier is engineered for adaptability, offering reliable performance even in complex site geometries. With the ability to form turns in precise 15-degree increments, the C122 system provides the flexibility needed to navigate corners and irregular layouts with ease.

Thanks to our innovative connection system—featuring adjustable rods and purpose-designed corner elements—assembling angled sections is both quick and intuitive. Whether you’re dealing with inner or outer turns, the C122’s universal corner components ensure a smooth, efficient setup without compromising structural integrity.

| Maximum Water Column / Dam height (A) | 152 cm |

| Set up time 90 degrees by 6 workers | 55 min |

| Section Weight | 78.4 kg |

| Turning radius / section | 15 degree |

| Extendable | No |

| Upper arc length (A) | 225 cm |

| Lower arc length (B) | 425 cm |

| Membrane length (C) | 825 cm |

| Turning radius | 525 cm |

| Sealer clips | 9 |

| Turning radius (G) | 315 cm |

| Lower inner arc length (F) | 225 cm |

| Lower outer arc length (E) | 495 cm |

| Upper arc length (D) | 415 cm |

| Membrane length | 415 m |

| Sealer clips | 9 |

| Material | High Strength low alloy steel |

| Dimensions | L177 x W32 x H6.5 cm |

| Weight | 23.4 kg |

| Quantity / section | 1 pc |

| Material | High Strength steel |

| Dimensions | min. L794 mm max. L1189 mm |

| Weight | 3.9 kg |

| Quantity / 90 degree corner | 6 pcs |

| Material | Zinc coated, galvanized steel |

| Dimensions | L215 x W50/32 |

| Weight | 12 kg |

| Quantity / 90 degree corner | 9 pcs |

| Material | PVC coated Low Density Polyethylene |

| Dimensions | L33 x W4.5 m - 420 g/m2 |

| Weight | 62 kg per roll |

| Quantity / 90 degree corner | 8 m |

| Material | Galvanized Steel DIN763 |

| Dimensions | L5 m x 12mm links excluding carabiners |

| Weight | 11.3 kg |

| Quantity / 90 degree corner | 9 m |

| Material | Nylon |

| Dimensions | L38 cm |

| Weight | 0.001 kg |

| Quantity / 90 degree corner | 16 pcs |

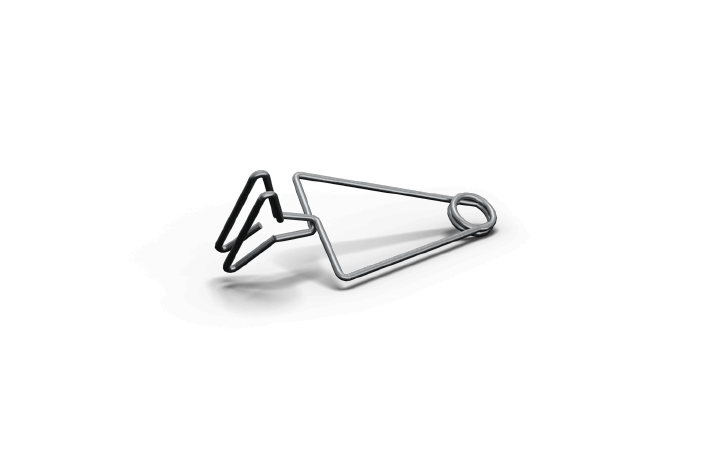

| Material | Steel |

| Dimensions | L17 cm |

| Weight | 0.08 kg |

| Quantity / 90 degree corner | 3 pcs |

Our step-by-step instructions are designed to guide you through the process of setting up your system quickly and easily. Even if you're new to the C152, our instructions are straightforward and easy to follow.

While we're confident that anyone can set up the C152 using our manual, we do recommend training and consultation for the best possible outcome. These additional resources can help you optimize your setup and ensure that everything runs smoothly.

Place the C122 Barrier Supports 122 cm apart. Use Link Bars to gauge the distance.

If installed on concrete

Prepare installation of Concrete Anchor. Drill a hole using a Hammer Drill.

If installed on concrete

Screw on the Concrete Anchors into the ground. Leave a distance of 1.5 cm between top of the anchor and the bottom beam of the C152 Barrier Supports.

Errect the C152 Barrier Supports. ❶ Lift the front beam up and ❷❸ unfold the support beams. Slide the inner support beam until it rests against the security axis.

Secure the C152 Barrier supports upright position with the Snap Lock. ❶ Push the protruding rods outward, ❷ then upward, ❸ until they pass through the cut-out.

❶ Insert the Z-lock on the Link bar into the keyhole cutout on the front beam. ❷ Lower it until the Z-lock rests at the bottom of the cutout.

Mount the 1071 Aluminum Panels by ❶ sliding the triangular cutout over the Link Bar. ❷ Lower it until the panel hangs on the protruding part.

Roll out the 4.5 m wide Geodesign Poly Membrane and secure with one Sealer Clip per section, along the top edge. Ensure that there is between 15-20 cm overlap at the back of the barrier.

Connect the chain lengths with karabiners and place them along the membrane's outer edge. ❶ Wrap or lay the chain on the membrane, ❷ thread a cable tie through the pre-punched holes, ❸ and secure the chain.

If installed on concrete

Seal the poly membrane to the ground by applying 20 cm wide sealing tape over both the chain and the membrane edge.

Hang the garland chain on the inclined part of the barriers. Fasten the chain to the C152 Barrier Supports using the carabiner hook.

Adjust the Sealer Clips as water enters the barrier to relax the Poly Membrane. Gently step on the membrane to squeeze out air pockets.

Installed and self-anchored as rising water presses the barriers to the ground.

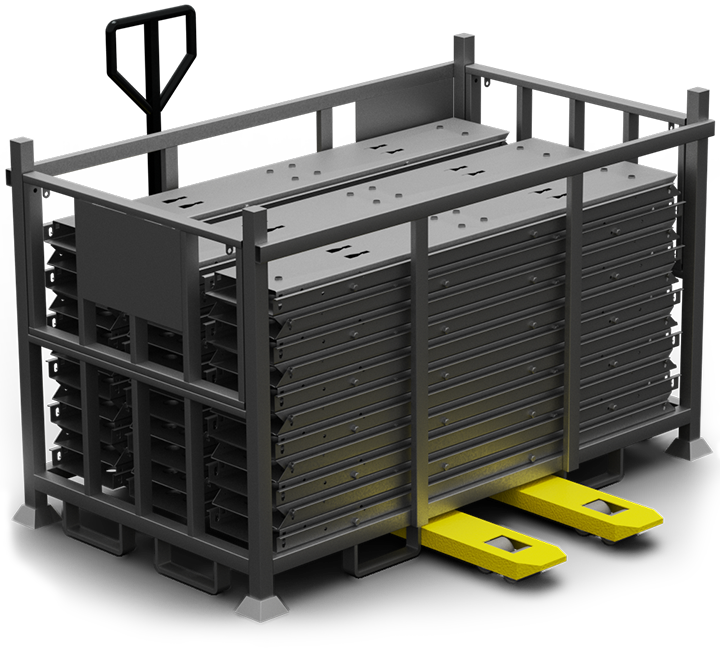

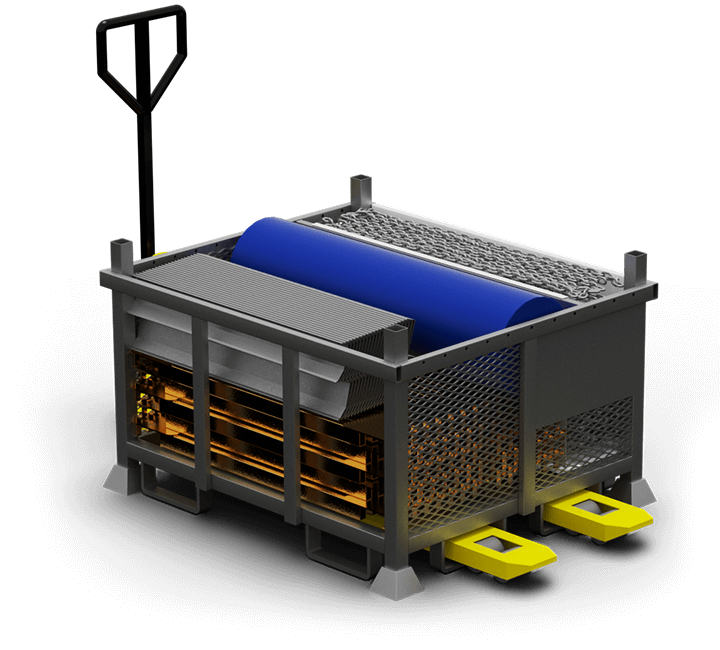

The C152 Heavy Duty System is shipped in durable, weatherproof metal crates designed for both delivery and long-term storage. Each crate is covered with a PVC hood to keep the contents dry and dust-free. These stackable crates are designed for space-efficient storage and can be easily moved with a manual forklift, offering flexible handling on-site.

| Material | Galvanized Steel |

| Dimensions | L1.4 x W1.15 x H0.88 m |

| Weight | 1550 kg |

| Quantity / crate |

90 alu sheets |

| Material | Galvanized Steel |

| Dimensions | L2.4 x W1.15 x H1.2 m |

| Weight | 1220 kg |

| Quantity / crate |

39 supports |

| Material | Galvanized Steel |

| Dimensions | L1.4 x W1.15 x H0.88 m |

| Weight | 750 kg |

| Quantity / crate |

Remaining components |

The C152 Heavy Duty system is efficiently packed in durable, stackable metal crates, all fitting neatly into a 20-foot container. This compact solution offers convenient storage and strategic placement, ensuring fast access and rapid deployment when needed. Simply position the container where it's required—no additional storage space is necessary.

| Combi crate: | 14 units |

| C152 support crate: | 9 units |

| Membrane shelf | 1 unit |

Discover how the C152 Heavy Duty Barrier can be your trusted solution for flood protection. Contact us today for expert guidance and a personalized quote tailored to your needs.