Industrial Flood Barrier: Easy, Flexible Major Flood Defense

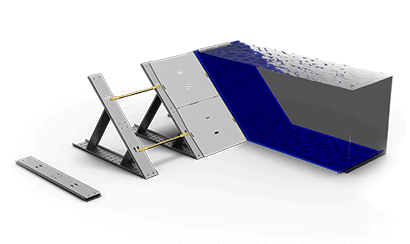

Geodesign's Industrial Flood Barrier is a highly effective solution for protecting large areas from flooding in a short amount of time. Available in four different models – 48 inches, 40 inches, 32 inches, and 24 inches – our system can be easily combined to create a customized solution tailored to the topography of any site.

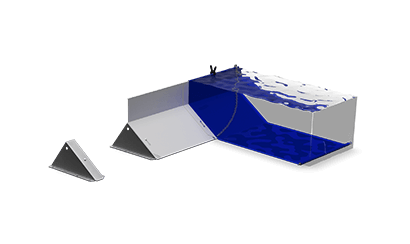

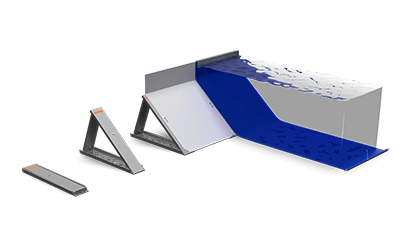

The Industrial Flood Barrier consists of two main metal components: a barrier support and a metal sheet covered in a plastic membrane. This unique design enables fast installation without the need for tools, heavy equipment, or a large workforce. The barrier's ingenious simplicity has made it a favorite among government entities for its logistical advantages.

Our Industrial series is designed for convenience and efficiency, offering compact storage with all necessary components for a 164-foot linear length optimized into a single, stackable metal crate. This streamlined approach allows for easy transport and deployment, making our Industrial series an ideal solution for large-scale flood protection.

Take the first step to flood protection - contact us now