Verify that the barrier system has quality certificates from a reputable third party. Flood operation activities and safety should always require certified products with rigorous testing and evaluation procedures as the standard.

Flood barriers

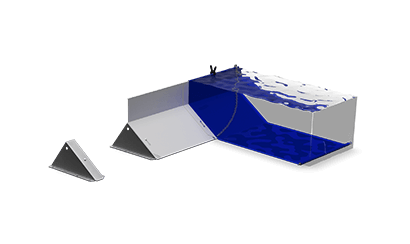

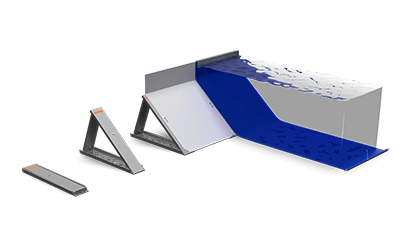

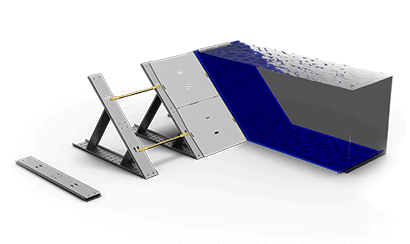

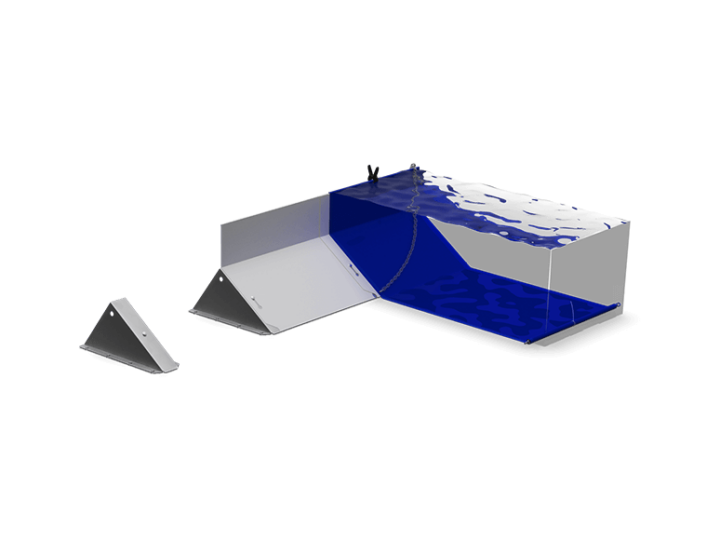

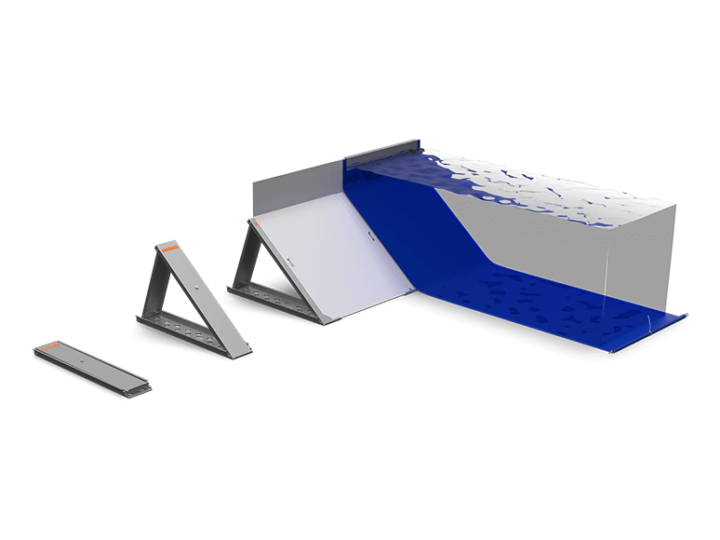

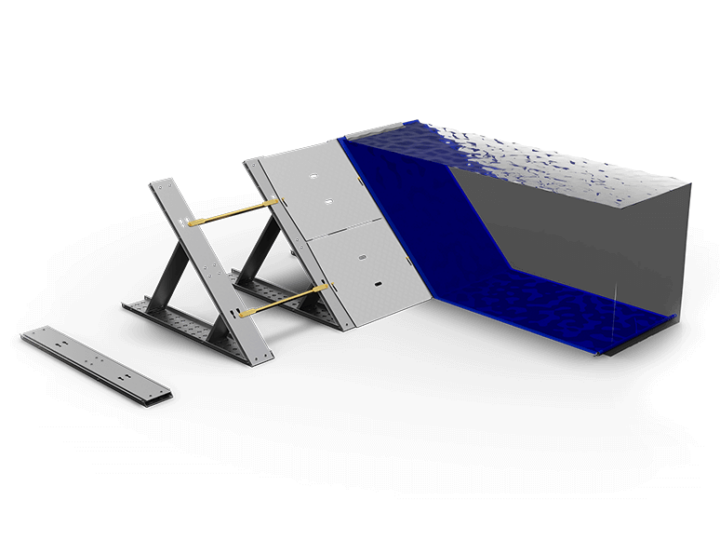

Geodesign offers three series of flood protection barriers with 11 models, designed to handle various flooding scenarios. Based on the same principle, they vary in dam height and design to suit specific needs. Ideal as both Commercial Flood Barriers and Flood Barriers for Homes, they can be quickly installed without tools, even in high-pressure situations.